vandjq wrote: .... I presume you are suggesting there may be some slack in the cable which might be take up by a slight tightening.

sort of; I'm actually suggesting that with some hubs there is slight mismatch between the insides of the hub and what the CJ marks are telling you. This appears to occur because of a manufacturing fault.

Does the adjuster tighten clockwise or anti-clockwise?

Daft answer I know but it depends which way you look at it. For N8 and early Alfine hubs (which are both 'low normal' i.e. they default to 1st gear with the cable disconnected) you need to unscrew the barrel adjuster on the shifter (i.e. turn it so that the top of the barrel adjuster moves forwards, i.e. in the direction of travel of the bicycle). Try two clicks (from 'perfect adjustment') first, then three, then four. If there is a CJ/hub mismatch then one of these settings should make the hub work better.

If there is an internal fault with the hub, then none of these settings will provide a perfect result.

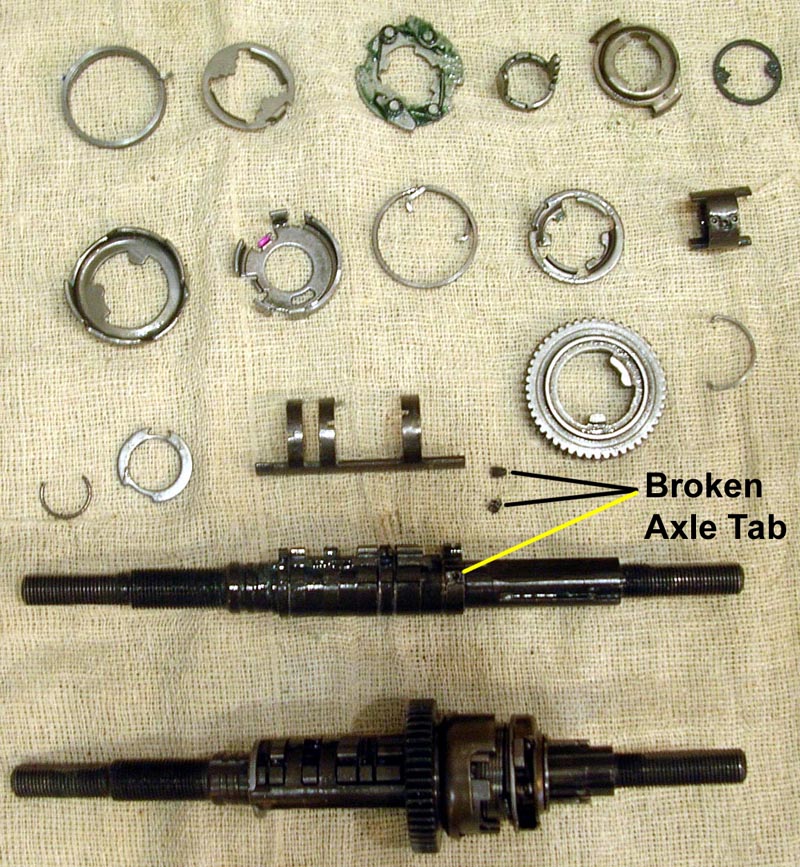

A caveat is that I have seen hubs where the sun locking pawls have become slightly damaged/worn through persistent slippage. In these hubs only a period of use with the correct setting (using lower power pedalling) with no slippage allows the parts to settle into one another properly again. Obviously there is no perfectly reliable way of making a determination that any slippage is caused by poor adjustment or by weird pawl wear; without opening up the hub all you can do is find the setting that works best, and use that.

cheers