IME rims wear most slowly when soft compound brake blocks are used and both the rim and brake block are kept clean. A very common cause of excessively fast rim wear is that particles (small stones and/or pieces of rim) get stuck the brake blocks. This makes a distinctive sound; if you must use the brakes anyway, bursts of 1s braking, 1s rest, and 1s braking again can often shift the particles; this seems to work because the particles melt the surrounding brake block material and are then more easily torn out of the surface of the brake block when the brakes are applied the second time. By contrast during continuous braking, the particles tend just to get pushed into the brake block further and further.

Examining the brake block faces and picking debris out of them is rarely time wasted; there is nearly always something there, rather than nothing. Note that the main source of particles may be the (new) rims themselves; pieces of swarf may be mashed into the surface during machining, yet not be visible and more to the point easily torn out of the surface and transferred to the brake block in use, rendering the brake block incredibly abrasive. Rims vary (even from the same maker) but it isn't that unusual to find that the first set of brake blocks on a new rims is quickly so contaminated that the best option is to fit replacements.

When the rim is too thin, it can fail suddenly; the tyre pressure tears the rim lip from the rim and the normal result is a dramatic blowout, with the wheel possibly jamming between the brakes as it happens.

So when to get concerned? Well this is easy enough if the rim has visible wear indicators; when they are no longer visible the rim is finished. Some rims have non-visible ('breakthrough' type) wear indicators; when the rim is worn out the wear indicators become visible, as the wear breaks into a cavity inside the rim.

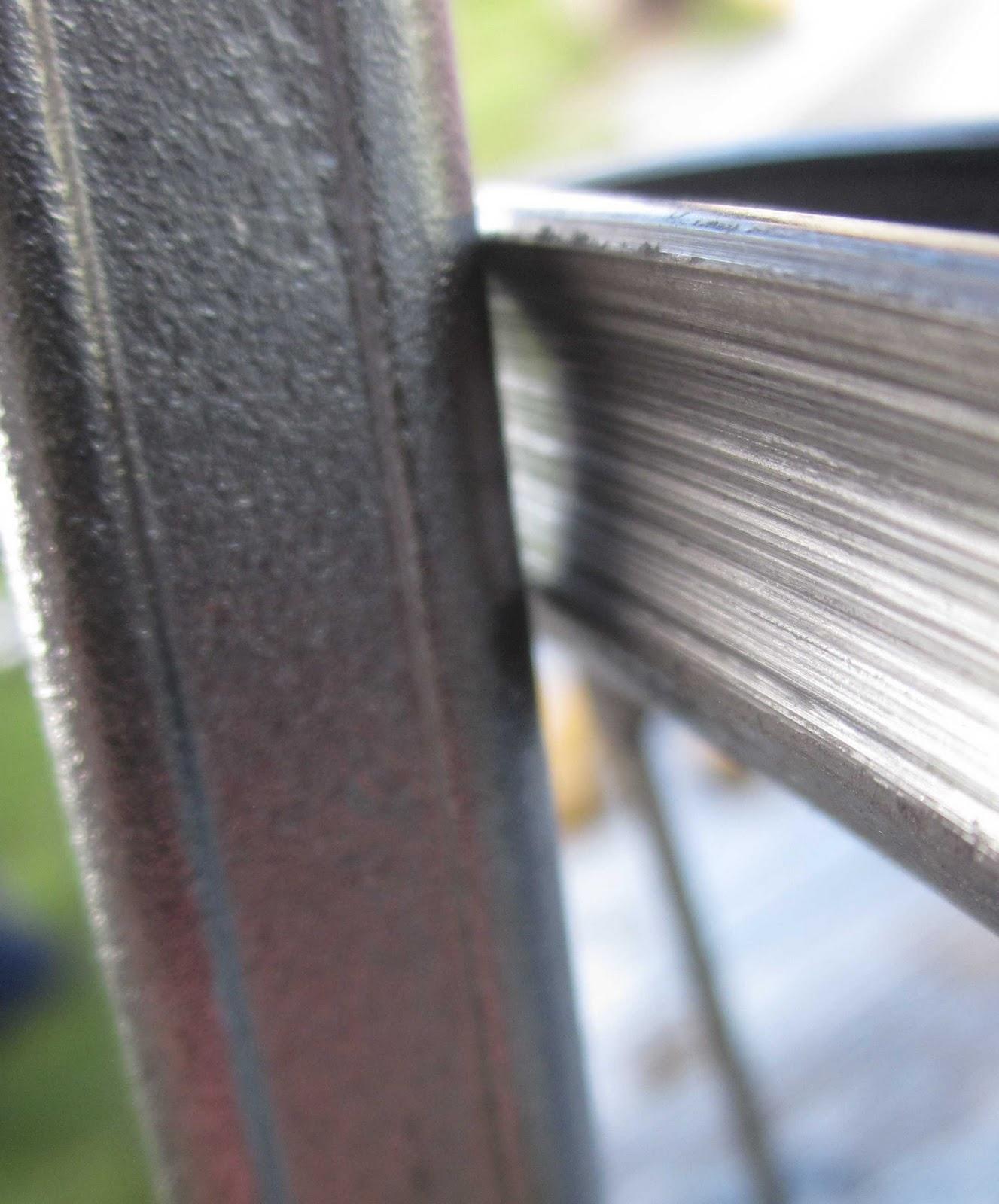

Ryde (Rigida) Sputnik rim, with a 'breakthrough' wear indication design

In any case there may be some warning of imminent failure, as the rim lips 'flare' outwards as the tyres are pumped up, or the braking becomes 'pulsy' as the rim flares more at one part than another. [NB modern rims are very rarely of uniform wall thickness, even if the extrusion is very well made, because rims are imperfectly fixtured before the braking surfaces are machined.]

However some rims don't have wear indicators at all, and others (such as those with breakthrough wear indicators) don't give much indication of how much life is left in the rim; this leaves you guessing if you are just about to head off on a tour; will your rims last the distance? Thus there is a need to measure the remaining rim thickness. It is necessary to measure at several locations to be sure of it, since wear need not be even and the rim didn't start out uniform thickness anyway. However once armed with this information, what do you do with it?

Most rims are 'perfectly safe' at 1.0mm wall thickness and get worse from there. Most still hang together at ~0.7mm thickness but not all, and it depends what tyre is fitted, how high the pressure is, how strong the material is, and whether there are any defects in the rim. Most folk know that a fatter tyre stresses the rim more at the same pressure, but beyond that don't have much of a feel for it.

For example which of these three creates more stress in the rim?

a) a 25mm tyre @ 90 psi, rim thickness of 0.8mm

b) a 23mm tyre @ 80psi, rim thickness of 0.7mm

c) a 28mm tyre @ 100psi, rim thickness of 0.9mm

Well the answer may surprise you; the 28mm tyre, (even though it is the largest section and the highest pressure) creates the least stress in the rim, the 25mm tyre case is ~15% worse than that, and the 23mm tyre, even at the lowest pressure, creates stresses that are about 40% higher than the 28mm tyre case.

The reason for this is that the effect of rim wall thickness is much more powerful than you might expect. The peak bending stresses in the rim go roughly with the cube of the thickness.

So taking a thickness of 1.0mm as a starting point;

thickness 1.0mm = starting stress

thickness 0.9mm = 1.37 x starting stress

thickness 0.8mm = 1.95 x starting stress

thickness 0.7mm = 2.92 x starting stress

thickness 0.6mm = 4.63 x starting stress

thickness 0.5mm = 8 x starting stress

so wearing from 1.0 to 0.8mm almost doubles the stress in the rim and wearing to 0.7mm almost triples it!

Additionally stresses are roughly pro-rata with tyre section and pressure. The ability of the rim to withstand it is also roughly in proportion to the strength of the material, which can be up to ~50% stronger in some cases than the weakest material. Thus at any given rim thickness you can create different stresses too. So comparing two cases;

A: 25mm tyre at 90psi on a rim of high strength material

B: 28mm tyre at 100psi on a rim of low strength material

the latter case means the rim is relatively over twice as stressed as the former. So if rim 'B' would start to fail with the tyre at just over 100psi (say) then rim A would accept a tyre pressure (in the 25mm tyre fitted) of over 180psi without risk of failure. Another way of looking at it is that rim A could be worn to a thickness of ~0.15 to ~0.2mm less than case B before the rim blows out.

The latter seems like a much smaller difference; you might not notice if the rim thickness drops by 0.15 or 0.2mm but this has just the same effect on the rim stresses as if you pumped your tyres up twice as hard as normal!

So one way of checking that the rims are not on the way out is to deliberately overpressure the tyres occasionally; this 'proof tests' both the tyre and the rim. For example if the tyres normally run at 80psi (say) instead of just pumping them up to 80psi and then riding, you could pump them to 100psi and see if the rim starts to deform or not. If they are OK at 100psi then deflate the tyres to the working pressure of 80psi and go ride that day, safe in the knowledge that you have a safety margin of at least 20%. Note that this only corresponds to about 50 microns (0.05mm) of rim wear though; two day's ride in moderately bad conditions or even a single day's ride in the worst conditions might still be enough to finish the rim off.

Bearing this in mind maybe testing by overpressuring to + 40% or +50% is a better idea; if the tyre or the rim fails during this test, it was on the way out anyway.....

cheers