In standard (drum brake or rim brake) hubs the driver has two pawls which are potentially disconnected by the actuator plate when freewheeling or backpedalling. In coaster brake hubs there are four pawls fitted; the two forward driving pawls work as per the non-coaster hubs; the other two pawls face backwards and engage with the brake mechanism. In coaster brake hubs the actuator plate needs to be in good order if the brake is to work correctly.

actuator plate shown in red, in the position where the driving pawls are pushed inwards (freewheeling or back pedalling). The empty pockets would hold the (extended) second pair of pawls in a coaster brake hub

shows how the sliding clutch can turn the actuator plate thus pushing the driver pawls out of engagement

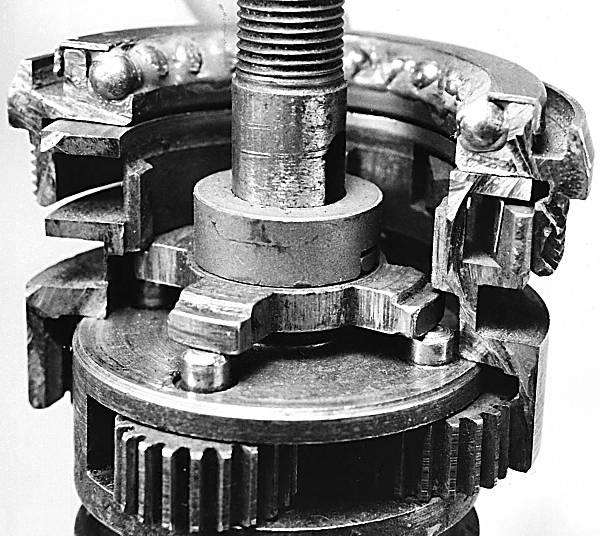

a four-pawl driver to fit a coaster-brake hub.

One of the things that sometimes fails inside the current 3s hub is the actuator plate. There appears to be two modes of failure

a) the plate comes separated from the driver and gets into the gap between the driver and the sliding clutch (eg in third gear) and then gets further broken up.

b) the 'ears' on the actuator plate break off and the shrapnel thus created further damages the hub.

I've seen both types of failure. At one time there were bikes being shipped with faulty actuator plates and bike shop owners were expected to change every single one they sold.

a) is still a problem; I suggest it is prudent every time you have a NIG hub apart to check the fit of the actuator plate. Usually it is pretty loose and because it is only retained by the 'D' shaped dimples in the side, it can faily easily slip off. This can happen when freewheeling or backpedalling in gear 1 or gear 2 and gear 3 is selected; the sliding clutch will tend to drag the actuator plate off the driver it it can. You can adjsut the fit of the actuator plate by bending it slightly. It shouldn't be a draggy fit on the driver, but it shouldn't be loose either.

b) is also a potential mode of failure. If you habitually backpedal or freewheel when shifting, the actuator plate has more work to do. I don't think it can last indefinitely in any case, but if it is in good condition when inspected, and the gears are usually shifted whilst pedalling forwards (without force until the gear is in) this will maximise the life of the actuator plate.

The highest forces on the actuator plate appear if you wheel the bike backwards in gear 3 whilst obstructing one pedal (e.g. with one foot on a pedal or with the kickstand extended). Some users report that their 3s hub works OK without an actuator plate fitted but if for some reason the sloping faces of the cutouts in the base of the sliding clutch don't work then the hub will be broken when wheeling the bike backwards in gear 3.

If you inspect the actuator plate and you find a crack in it, it must be replaced. I recently found this picture on the interweb which rather suggests that SA have at times been shipping parts which arrive with a crack in them; no wonder they sometimes break;

there seems to be a crack in the actuator plate on this new part.

You can remove the driver and change the actuator plate in about fifteen minutes; you don't have to remove the entire internal to do it, you just have to unscrew the RH cone to gain access. Whilst you are at it, it is an excellent idea to fit the correct lockwasher between the RH cone and locknut too.

part HMW147; deemed as essential in SA hubs for at least sixty years, now not fitted by SA presumably in the name of cost-saving

The manufacturing costs of a washer like that are fractions of a penny; without it the RH cone can precess into the hub workings and destroy the hub (and with it SA's reputation). Talk about false economy....

cheers