Spoke Tension Meter, Hows This Work?

- NATURAL ANKLING

- Posts: 13780

- Joined: 24 Oct 2012, 10:43pm

- Location: English Riviera

Spoke Tension Meter, Hows This Work?

Hi,

My only guess is that the thing friction locks at the scale end, when the spring allows the pivot to drop in the slot (weak tension), if the spring is too weak to allow this then the scale indicator will freely move in the graduated slot.

https://www.ebay.co.uk/itm/Bicycle-Whee ... k:190:pf:0

My only guess is that the thing friction locks at the scale end, when the spring allows the pivot to drop in the slot (weak tension), if the spring is too weak to allow this then the scale indicator will freely move in the graduated slot.

https://www.ebay.co.uk/itm/Bicycle-Whee ... k:190:pf:0

NA Thinks Just End 2 End Return + Bivvy - Some day Soon I hope

You'll Still Find Me At The Top Of A Hill

Please forgive the poor Grammar I blame it on my mobile and phat thinkers.

You'll Still Find Me At The Top Of A Hill

Please forgive the poor Grammar I blame it on my mobile and phat thinkers.

Re: Spoke Tension Meter, Hows This Work?

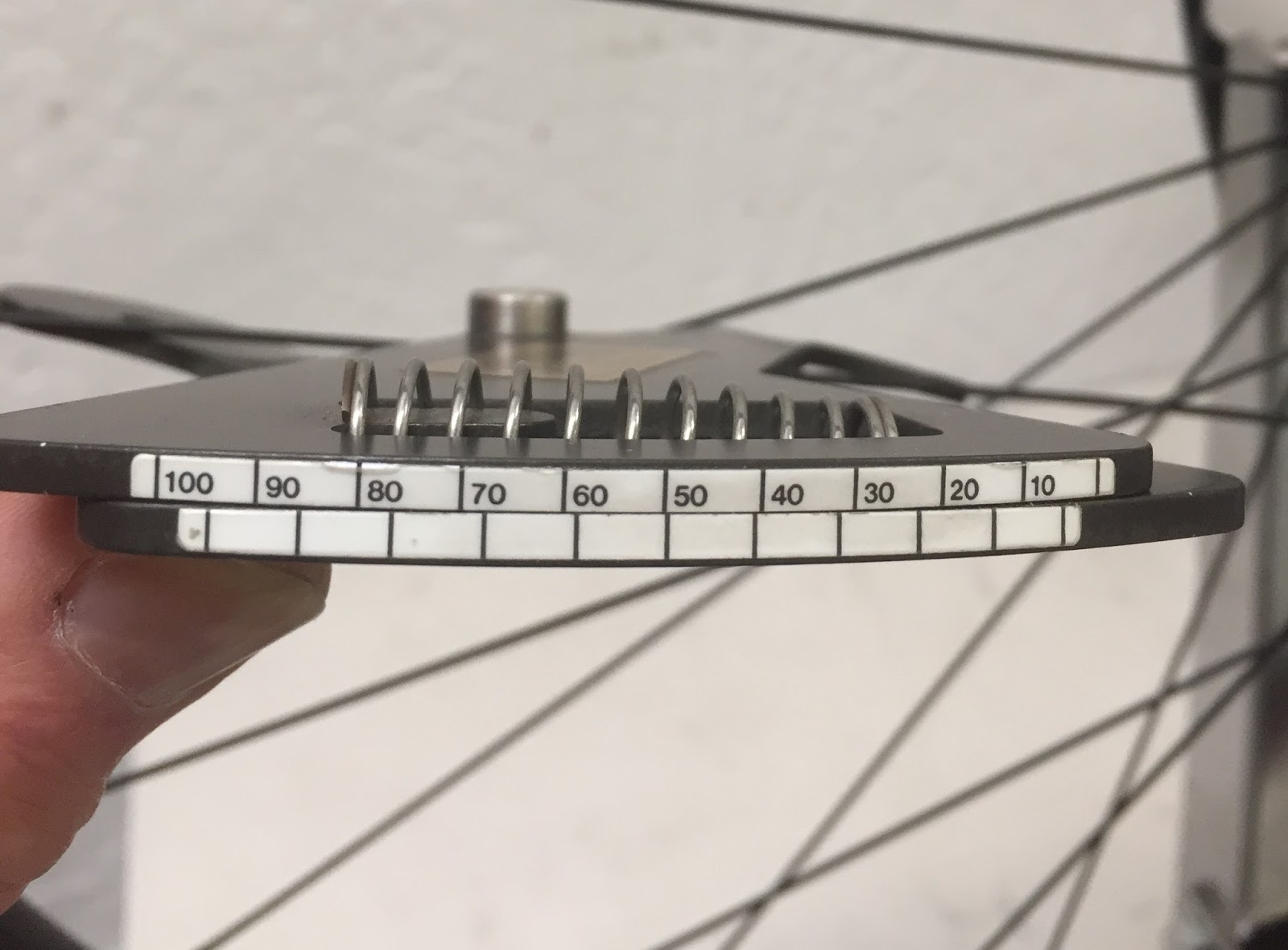

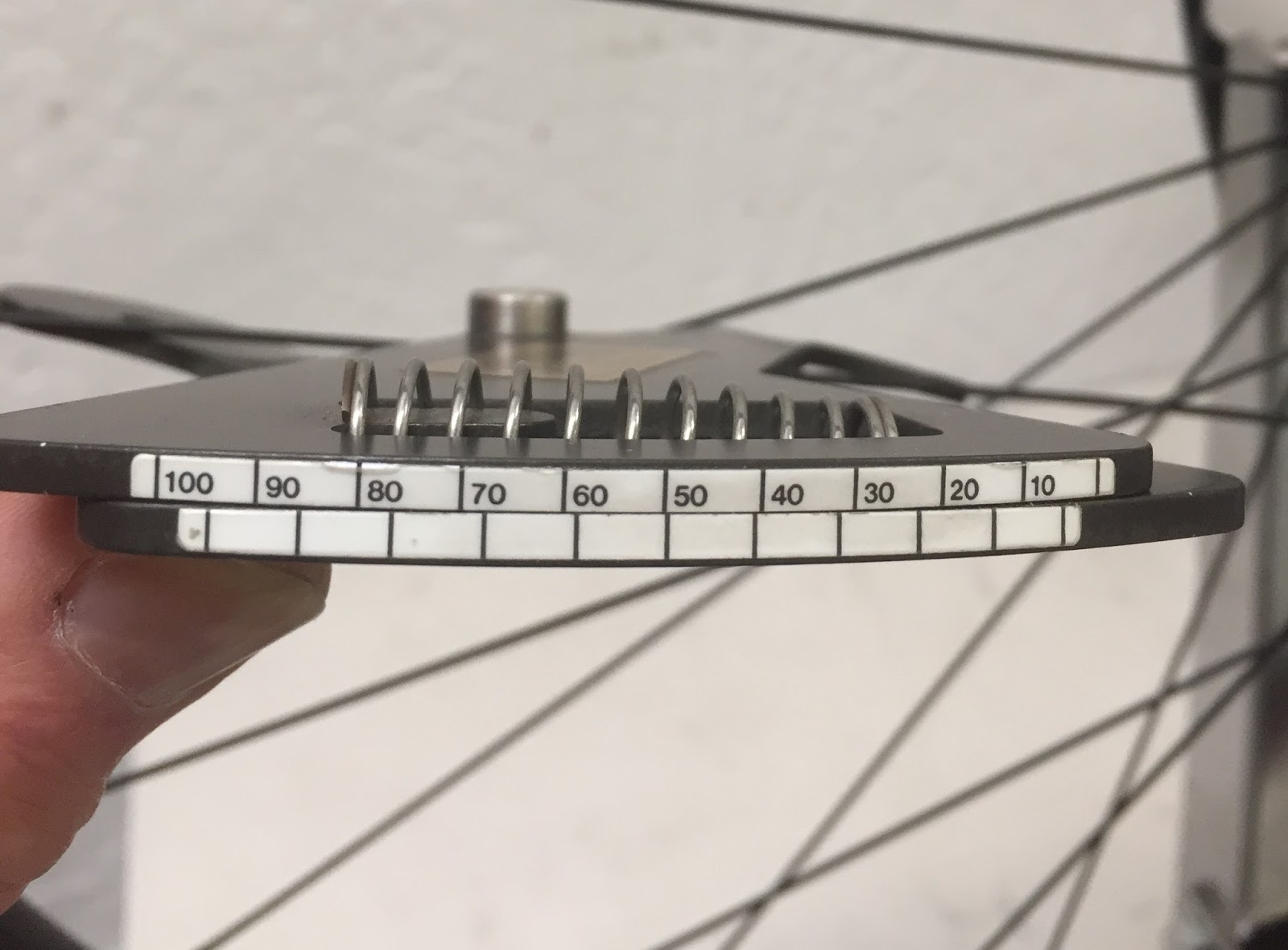

the moving part pivots around a bushing (the one with the spring turns around it) which is offset wrt to the middle fulcrum. The spring pushes the moving part towards the zero on the scale.

To use the tension meter, squeeze the tool (so that the indicator moves to the high end of the scale), offer it over the spoke and then gently release the tool. The spoke will be trapped by the spring loaded fulcrums and the indicator will move closer to the zero end of the scale if the spoke has little tension and/or is more easily bent (material, thickness, cross section). If the spoke is thick, stiff, or has a high tension in it then the pointer doesn't move far and you get a high reading.

You turn the tool reading into a tension by then using a lookup chart.

The tool pictured is a knock-off of the park tool version. If you read the park tool blurb you will get a good impression of how the tool works.

IME such tools are better than nothing but only just; getting really consistent readings is difficult for several reasons, and the calibration can quite easily go wonky. However if you feel you need a sanity check on your spoke tension then it is OK. For getting uniform tension in a single wheel, plucking spokes is almost invariably both faster and better.

cheers

To use the tension meter, squeeze the tool (so that the indicator moves to the high end of the scale), offer it over the spoke and then gently release the tool. The spoke will be trapped by the spring loaded fulcrums and the indicator will move closer to the zero end of the scale if the spoke has little tension and/or is more easily bent (material, thickness, cross section). If the spoke is thick, stiff, or has a high tension in it then the pointer doesn't move far and you get a high reading.

You turn the tool reading into a tension by then using a lookup chart.

The tool pictured is a knock-off of the park tool version. If you read the park tool blurb you will get a good impression of how the tool works.

IME such tools are better than nothing but only just; getting really consistent readings is difficult for several reasons, and the calibration can quite easily go wonky. However if you feel you need a sanity check on your spoke tension then it is OK. For getting uniform tension in a single wheel, plucking spokes is almost invariably both faster and better.

cheers

-------------------------------------------------------------------------------

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

- NATURAL ANKLING

- Posts: 13780

- Joined: 24 Oct 2012, 10:43pm

- Location: English Riviera

Re: Spoke Tension Meter, Hows This Work?

Hi,

Ah, you'll forgive my ignorance as I have never seen any tool to check spoke tension ever.

So I see from their website it works opposite to what I imagined

If I am not building modern low spoke count wheels then do I need one, I have got this far.

If yes what's best tool and is it purely a mechanical device.

Ta,

Ah, you'll forgive my ignorance as I have never seen any tool to check spoke tension ever.

So I see from their website it works opposite to what I imagined

If I am not building modern low spoke count wheels then do I need one, I have got this far.

If yes what's best tool and is it purely a mechanical device.

Ta,

NA Thinks Just End 2 End Return + Bivvy - Some day Soon I hope

You'll Still Find Me At The Top Of A Hill

Please forgive the poor Grammar I blame it on my mobile and phat thinkers.

You'll Still Find Me At The Top Of A Hill

Please forgive the poor Grammar I blame it on my mobile and phat thinkers.

Re: Spoke Tension Meter, Hows This Work?

do you need one?

Well if the spoke tension is too low then the spokes move and wear in the hub, if the nipples are threadlocked. If there is no threadlock then the nipples will back out in use if the tension isn't high enough.

If the tension is too high then a wheel with a single-wall rim will self-pretzel. With a twinwall rim if the tension is too high then the rim will crack after a while, usually on the rear driveside spoke holes. If you get it really wrong the spoke may pull through the rim....

So you don't really need a tension meter if your wheels don't do these things and you are building with rims and spokes that are well-known to you.

Even if you do have a tension meter you can still come unstuck; some rims detension the spokes when a tyre is fitted and inflated, so a tension meter can tell you the wheel is fine, but when a tyre is fitted the spokes are suddenly too loose. The tool can be useful but it is no substitute for common sense and experience.

BTW if you want to 'calibrate' your spoke tensions in built wheels (and you are not tone deaf) you can hang a (say) 100kg weight up with a spoke. The spoke ought to be of the same length as is used in a built wheel. Unbrace one crossing in a built wheel (or just use a radial spoked wheel) and get the wheel true again by retensioning the spokes correctly. Then compare the plucked note of the unbraced spokes with that of the weighted spoke. Unbraced spokes give a very clean primary tone in a wheel (whereas braced ones give a muddy tone with more harmonics in it). This will be the same tone as you will get in the weighted spoke, provided both ends of the weighted spoke are restrained laterally.

cheers

Well if the spoke tension is too low then the spokes move and wear in the hub, if the nipples are threadlocked. If there is no threadlock then the nipples will back out in use if the tension isn't high enough.

If the tension is too high then a wheel with a single-wall rim will self-pretzel. With a twinwall rim if the tension is too high then the rim will crack after a while, usually on the rear driveside spoke holes. If you get it really wrong the spoke may pull through the rim....

So you don't really need a tension meter if your wheels don't do these things and you are building with rims and spokes that are well-known to you.

Even if you do have a tension meter you can still come unstuck; some rims detension the spokes when a tyre is fitted and inflated, so a tension meter can tell you the wheel is fine, but when a tyre is fitted the spokes are suddenly too loose. The tool can be useful but it is no substitute for common sense and experience.

BTW if you want to 'calibrate' your spoke tensions in built wheels (and you are not tone deaf) you can hang a (say) 100kg weight up with a spoke. The spoke ought to be of the same length as is used in a built wheel. Unbrace one crossing in a built wheel (or just use a radial spoked wheel) and get the wheel true again by retensioning the spokes correctly. Then compare the plucked note of the unbraced spokes with that of the weighted spoke. Unbraced spokes give a very clean primary tone in a wheel (whereas braced ones give a muddy tone with more harmonics in it). This will be the same tone as you will get in the weighted spoke, provided both ends of the weighted spoke are restrained laterally.

cheers

-------------------------------------------------------------------------------

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

Re: Spoke Tension Meter, Hows This Work?

You may be interested in Norm Ogle’s simple but ingenious Wheelsmith design, NA. Read about it here. Examples show up on eBay often.

I think I would try to get one of these in preference to the Park Tool design if I didn’t have my Jobst Brandt design tensiometer (the operation of which may also intrigue you – worth reading up on).

I think I would try to get one of these in preference to the Park Tool design if I didn’t have my Jobst Brandt design tensiometer (the operation of which may also intrigue you – worth reading up on).

I like the Park Tool TM-1 - works for me

I like my Park Tool TM-1. Bear in mind I am new to building complete wheels, and probably tone deaf, so having reference points for 1000N, 1200N etc is quite useful to me - I can make sure I don't exceed these tensions on the drive side, depending on the rim. Of course I am not sure how empirically accurate the gauge is (or needs to be?) but it is also good at comparing and equalising the tension between the spokes. Taking multiple readings of the same spoke tension does yield consistent results although the way your release the tool can make a difference, I try to always do it the same way. Park Tool have an online app where you can get an "at a glance" visual representation of the wheel as well (based on the spoke tensions you input - see second diagram below) and I have found this helpful... I have only built "overkill" wheels with it so far (36 spoke Sputnik, ZAC19 and ML21) but they have held up well in touring use including loaded cycle camping and on my tandem.

Re: Spoke Tension Meter, Hows This Work?

Norm Ogle's design is very simple but it is slightly different in use vs other tension meters; one reason for this is that one leg goes each side of the spoke so that the tension meter needs to be rotated slightly as it is fitted to the spoke rather than slid into position from one side only. Some will prefer one to the other and indeed using a meter of either type may be easier on wheels than others because of access etc.

It also has a Vernier type scale on it;

which some folk will love and others will struggle to read; in the photo above the reading is just less than '50' rather than just over '50' and some folk will not easily see the difference.

Fundamentally you can design these meters with strong or weak springs in them and they will be sensitive to different things; it isn't safe to use a calibration chart for one tension meter with a differnt type of tension meter even if you have checked the calibration for one type of spoke; it may not read across for other types of spoke.

All meters of this type (with the exception of the Brandt design which takes slightly longer to use properly) suffer from the same problems; spokes that are not straight give anomalous readings (moreso for light spring loads than heavy spring loads) and any small variation (reduction) in spoke diameter can cause the meter to over-read (moreseo for heavy spring loads than light ones I think) for two reasons;

1) the displacement (meter reading) is increased simply because the spoke is thinner and

2) the spoke is bendier because it is thinner which also increases the meter reading

so it is something of a double-whammy. I have measured nominally 14G spokes (should be 2.0mm) and batches vary from just over 1.9mm to 1.99mm; they won't read the same on an average tension meter.

Currently you can buy a park-tool-alike meter from CRC/wiggle for £29; no idea if it is actually any good or not.

cheers

It also has a Vernier type scale on it;

which some folk will love and others will struggle to read; in the photo above the reading is just less than '50' rather than just over '50' and some folk will not easily see the difference.

Fundamentally you can design these meters with strong or weak springs in them and they will be sensitive to different things; it isn't safe to use a calibration chart for one tension meter with a differnt type of tension meter even if you have checked the calibration for one type of spoke; it may not read across for other types of spoke.

All meters of this type (with the exception of the Brandt design which takes slightly longer to use properly) suffer from the same problems; spokes that are not straight give anomalous readings (moreso for light spring loads than heavy spring loads) and any small variation (reduction) in spoke diameter can cause the meter to over-read (moreseo for heavy spring loads than light ones I think) for two reasons;

1) the displacement (meter reading) is increased simply because the spoke is thinner and

2) the spoke is bendier because it is thinner which also increases the meter reading

so it is something of a double-whammy. I have measured nominally 14G spokes (should be 2.0mm) and batches vary from just over 1.9mm to 1.99mm; they won't read the same on an average tension meter.

Currently you can buy a park-tool-alike meter from CRC/wiggle for £29; no idea if it is actually any good or not.

cheers

-------------------------------------------------------------------------------

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

Re: Spoke Tension Meter, Hows This Work?

I had a couple of 27" wheels trued by my LBS but suffered from broken (galvanised) spokes due to inadequate tension. therefore I decided I could do just as well. I built several wheels by judgement and they were OK, but I have always found it hard to pluck spokes and hear anything meaningful. I find squeezing the spokes together is better for me. Having bought a tension meter I find it helps get uniform tensions in the spokes. I'm happy to get the basic tension by feel and am not too bothered what value the tension is but like to check the uniformity.

-

Airsporter1st

- Posts: 792

- Joined: 8 Oct 2016, 3:14pm

Re: Spoke Tension Meter, Hows This Work?

Post deleted. Unnecessarily condescending response below.

Last edited by Airsporter1st on 26 Dec 2018, 7:07am, edited 2 times in total.

Re: Spoke Tension Meter, Hows This Work?

arguably the fact that you felt you had to say that kind of underlines my point....

cheers

cheers

-------------------------------------------------------------------------------

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

Re: Spoke Tension Meter, Hows This Work?

gxaustin wrote:...I built several wheels by judgement and they were OK, but I have always found it hard to pluck spokes and hear anything meaningful. I find squeezing the spokes together is better for me. Having bought a tension meter I find it helps get uniform tensions in the spokes. I'm happy to get the basic tension by feel and am not too bothered what value the tension is but like to check the uniformity.

+1 or ditto

I’ve just bought a tension gauge to check uniformity. Have been an occasional wheel builder for many years, by feel alone and have not had a failure yet, but, despite being a musician, I have always found it difficult comparing the impure tones from plucked spokes.

Now I badly need an excuse to be building more wheels! I may have to just have a tweak of my summer bike wheels in order to play with the gauge.

Re: Spoke Tension Meter, Hows This Work?

I may have to just have a tweak of my summer bike wheels in order to play with the gauge.

I'm sure you'll find the variation, if any, in spoke tension very interesting

- NATURAL ANKLING

- Posts: 13780

- Joined: 24 Oct 2012, 10:43pm

- Location: English Riviera

Re: Spoke Tension Meter, Hows This Work?

Hi,

What sort of percentage of variation between spokes one side is acceptable?

Or is the meter readings too crude / influence by operator / poor repeatable reading, etc.

So you can fiddle it to read the same / satisfy yourself they are the same in different spokes.

Depends on the meter I suppose.

Already been answered earlier by Brucey partly.

I sometimes find I have one looser / tighter spoke but wheel is true.

My poor method or warped stiff rim or just impossible build.

If it stays together and spokes do not fail / loosen then alls ok anyway.

What sort of percentage of variation between spokes one side is acceptable?

Or is the meter readings too crude / influence by operator / poor repeatable reading, etc.

So you can fiddle it to read the same / satisfy yourself they are the same in different spokes.

Depends on the meter I suppose.

Already been answered earlier by Brucey partly.

I sometimes find I have one looser / tighter spoke but wheel is true.

My poor method or warped stiff rim or just impossible build.

If it stays together and spokes do not fail / loosen then alls ok anyway.

NA Thinks Just End 2 End Return + Bivvy - Some day Soon I hope

You'll Still Find Me At The Top Of A Hill

Please forgive the poor Grammar I blame it on my mobile and phat thinkers.

You'll Still Find Me At The Top Of A Hill

Please forgive the poor Grammar I blame it on my mobile and phat thinkers.

Re: Spoke Tension Meter, Hows This Work?

if you start with a rim that is not straight then you cannot build a wheel that is both true and evenly tensioned. Uneven tension risks several things

1) the nipples on the slackest spokes back out

2) the in-service tension variations in some of the spokes may be greater than normal which can cause spokes to break prematurely and even the rim to crack. For example a spoke that is slacker than normal will go fully slack in service and this is invariably a bad thing.

3) the spoke tension limit for the rim is liable to be exceeded on the tighter spokes.

I have quite often seen a rim that has cracked at one of the DS drillings near the rim joint, presumably where one or more spokes was overly tensioned in order to make the wheel round despite a poor rim joint.

In very many dished rear wheels you have DS spokes that are nudging the tension limit anyway, and NDS spokes that are slack enough that they will go full slack in hard service; in such cases it is only just possible to build a reliable wheel if you use a perfectly true rim. If you start with a slightly wonky rim the wheel will be no good. With front wheels there is usually a little more leeway.

cheers

1) the nipples on the slackest spokes back out

2) the in-service tension variations in some of the spokes may be greater than normal which can cause spokes to break prematurely and even the rim to crack. For example a spoke that is slacker than normal will go fully slack in service and this is invariably a bad thing.

3) the spoke tension limit for the rim is liable to be exceeded on the tighter spokes.

I have quite often seen a rim that has cracked at one of the DS drillings near the rim joint, presumably where one or more spokes was overly tensioned in order to make the wheel round despite a poor rim joint.

In very many dished rear wheels you have DS spokes that are nudging the tension limit anyway, and NDS spokes that are slack enough that they will go full slack in hard service; in such cases it is only just possible to build a reliable wheel if you use a perfectly true rim. If you start with a slightly wonky rim the wheel will be no good. With front wheels there is usually a little more leeway.

cheers

-------------------------------------------------------------------------------

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

Spoke Tension Meter, Hows This Work?

Brucey wrote:

In very many dished rear wheels you have DS spokes that are nudging the tension limit anyway, and NDS spokes that are slack enough that they will go full slack in hard service; in such cases it is only just possible to build a reliable wheel if you use a perfectly true rim. If you start with a slightly wonky rim the wheel will be no good. With front wheels there is usually a little more leeway.

cheers

IMO, you should use some form of threadlocker on the NDS spokes to keep the spoke nipples from loosening. Spoke tension alone is inadequate for a wheel with 130mm OLN hubs to keep NDS spoke nipples from loosening.