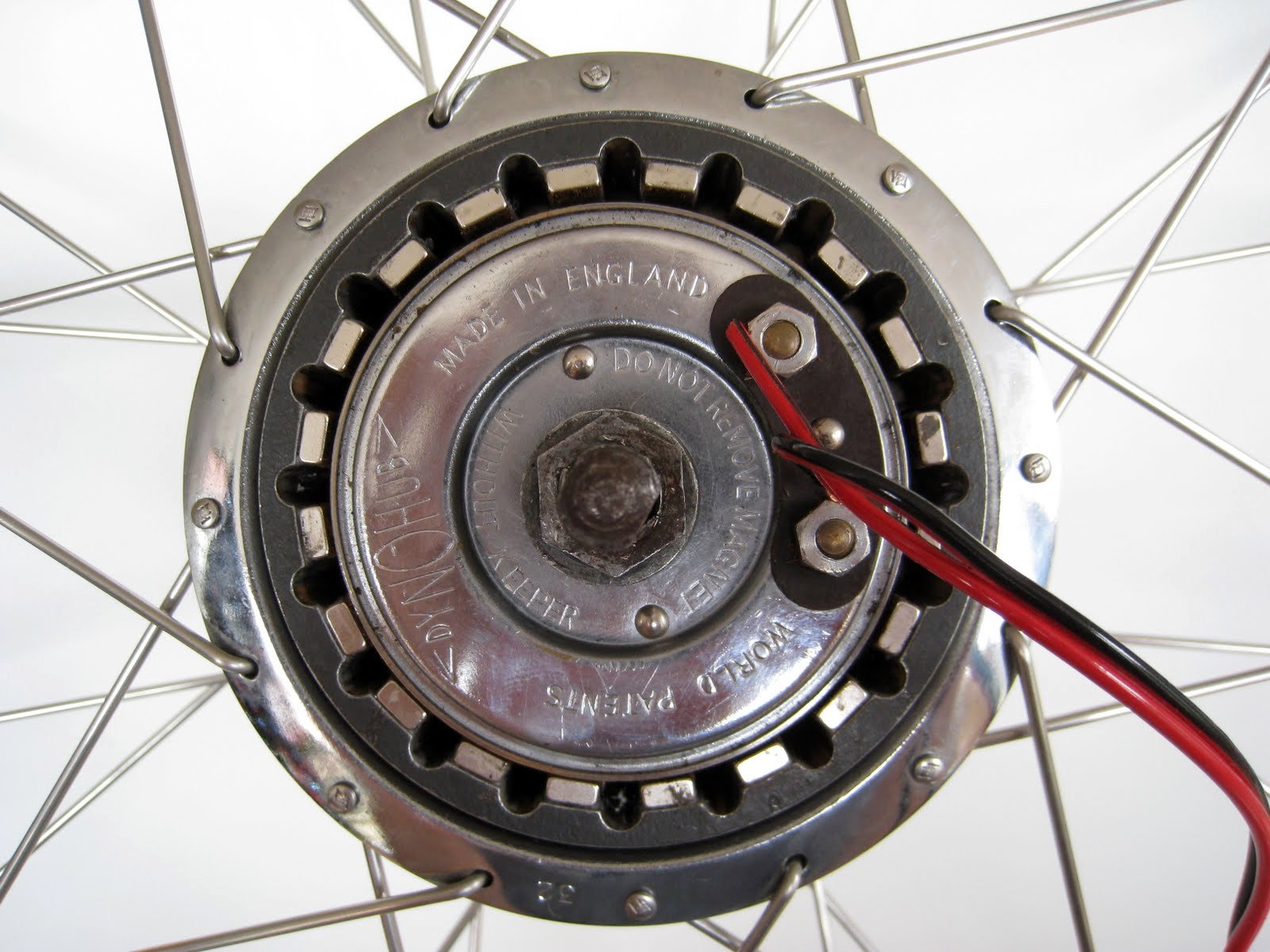

Sa ag/fg/gh6 dynohubs: why no modern magnet ring spares

Sa ag/fg/gh6 dynohubs: why no modern magnet ring spares

Given the amount of sturmey original dynohubs (i.e. gh6 ag fg) in the world it seems strange no one makes a modern magnetic materials magnet ring as a spare, especially now the stzvo have begat 1.5w led lighting officially. These would then have the advantage of not losing magnetism when next owner dismantles it...

------------You may not use this post in Cycle or other magazine ------

Re: Sa ag/fg/gh6 dynohubs: why no modern magnet ring spares

As an retired loudspeaker engineer who has designed many magnet systems I can tell you that changing the magnetic material in an existing design is not trivial. Different materials have to be used at specific cross sectional area vs magnetic length to work at optimal magnetic efficiently.

Re: Sa ag/fg/gh6 dynohubs: why no modern magnet ring spares

There's some advice on modifying sturmey dynohubs on t'interweb if you search. Here's one of many I found using neodymium magnets. The same thought crossed my mind.

https://www.candlepowerforums.com/vb/sh ... et-upgrade

https://www.candlepowerforums.com/vb/sh ... et-upgrade

At the last count:- Peugeot 531 pro, Dawes Discovery Tandem, Dawes Kingpin X3, Raleigh 20 stowaway X2, 1965 Moulton deluxe, Falcon K2 MTB dropped bar tourer, Rudge Bi frame folder, Longstaff trike conversion on a Giant XTC 840

Re: Sa ag/fg/gh6 dynohubs: why no modern magnet ring spares

Folk have done DIY conversions using modern magnets. eg

http://minisystem.blogspot.com/2011/11/sturmey-archer-dynohub-magnet-upgrade.html

This is made easier by the fact that modern permanent magnet materials require much less space, so the magnet assembly can be made much smaller and lighter than before.

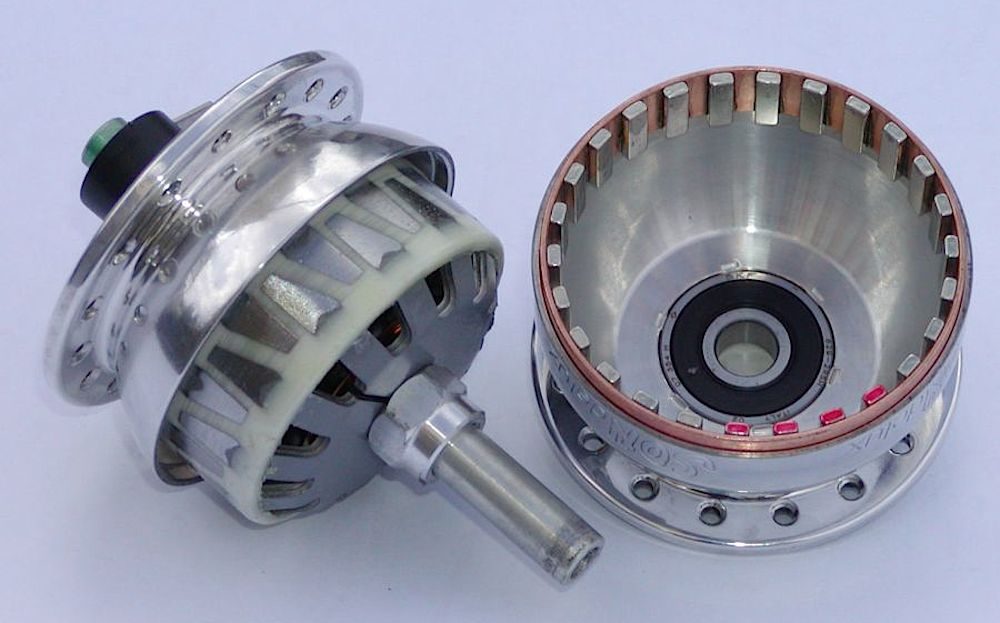

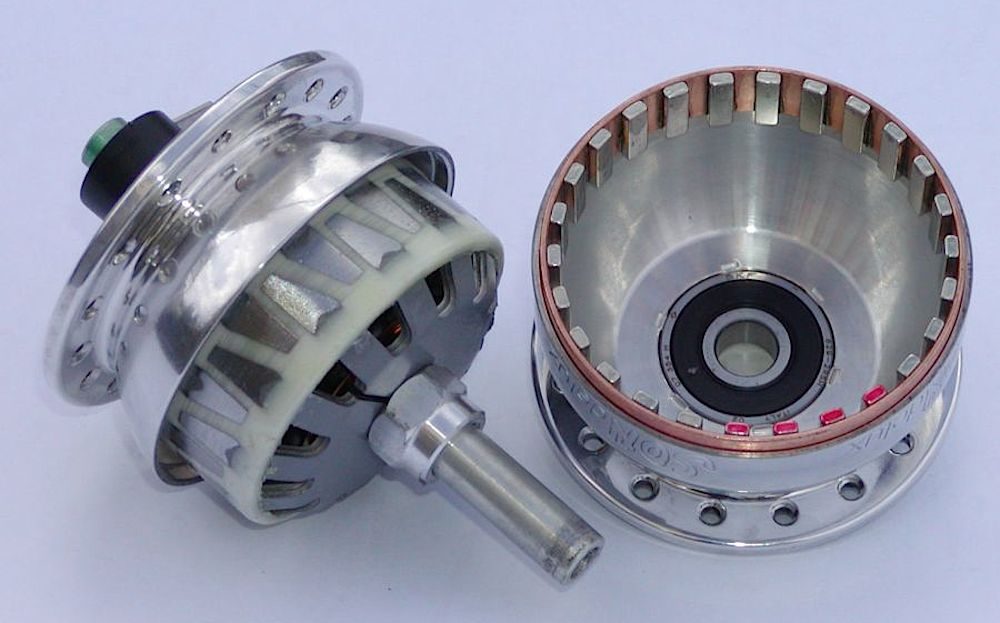

The photo below shows how a SON hub generator is put together;

the copper coloured ring is (I believe) copper plated iron; the copper plating gives some corrosion protection and gives better bonding for the magnets (glues stick better to copper plated surfaces than many others). The ring doesn't need to have super magnetic properties because the field running through it doesn't change that much. By contrast the soft iron pole pieces in the 'claw pole' configuration stator have constantly reversing field in them and magnetic hysteresis losses therein can be a significant source of inefficiency in the generator.

If you make up a similar arrangement using modern rare earth magnets, sized to fit a GH6 stator, you can quite easily get a lot more electricity out of the thing.

However if you were intending to drive tungsten bubs (with no regulator etc) with a modified generator then it would be very difficult to do a good job. As it is, modern lamps make good use of pretty much whatever a GH6 stator is going to chuck out and if there is more than is normal/necessary a modern LED headlamp will cope. So you don't have to shoot for the moon here, and it isn't that difficult to get a bit more oomph out of a generator of this sort; you don't need 'audiophile quality electricity'.

FWIW most hub generators are effectively current limited and the GH6 is no exception. I think you will get more current than normal but not as much as you might want. What those who have done this conversion usually seem to find is that you can get more volts (at speed) as well. That combined with the fact that LEDs give useful amounts of light even at low powers probably means that a pair of cheap LED headlights (some of which reach full brightness at about 4V AC) in series would give modern amounts of light from the old stator. But as per the link above a parallel arrangement could work OK too; possibly the stators vary with the original magnet type (there was more than one different sort used by SA) .

Also it wouldn't be that difficult to dismantle the claw poles and fit a different coil if you wanted either, such that you got fewer volts and more current if that suited you.

The reason why no-one offers a conversion kit is because there probably isn't any money in it. How much would you think such a kit would sell for?

cheers

http://minisystem.blogspot.com/2011/11/sturmey-archer-dynohub-magnet-upgrade.html

This is made easier by the fact that modern permanent magnet materials require much less space, so the magnet assembly can be made much smaller and lighter than before.

The photo below shows how a SON hub generator is put together;

the copper coloured ring is (I believe) copper plated iron; the copper plating gives some corrosion protection and gives better bonding for the magnets (glues stick better to copper plated surfaces than many others). The ring doesn't need to have super magnetic properties because the field running through it doesn't change that much. By contrast the soft iron pole pieces in the 'claw pole' configuration stator have constantly reversing field in them and magnetic hysteresis losses therein can be a significant source of inefficiency in the generator.

If you make up a similar arrangement using modern rare earth magnets, sized to fit a GH6 stator, you can quite easily get a lot more electricity out of the thing.

However if you were intending to drive tungsten bubs (with no regulator etc) with a modified generator then it would be very difficult to do a good job. As it is, modern lamps make good use of pretty much whatever a GH6 stator is going to chuck out and if there is more than is normal/necessary a modern LED headlamp will cope. So you don't have to shoot for the moon here, and it isn't that difficult to get a bit more oomph out of a generator of this sort; you don't need 'audiophile quality electricity'.

FWIW most hub generators are effectively current limited and the GH6 is no exception. I think you will get more current than normal but not as much as you might want. What those who have done this conversion usually seem to find is that you can get more volts (at speed) as well. That combined with the fact that LEDs give useful amounts of light even at low powers probably means that a pair of cheap LED headlights (some of which reach full brightness at about 4V AC) in series would give modern amounts of light from the old stator. But as per the link above a parallel arrangement could work OK too; possibly the stators vary with the original magnet type (there was more than one different sort used by SA) .

Also it wouldn't be that difficult to dismantle the claw poles and fit a different coil if you wanted either, such that you got fewer volts and more current if that suited you.

The reason why no-one offers a conversion kit is because there probably isn't any money in it. How much would you think such a kit would sell for?

cheers

-------------------------------------------------------------------------------

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

Re: Sa ag/fg/gh6 dynohubs: why no modern magnet ring spares

this photo is of the insides of a Union-Marwi 'Wing III' generator (which is in essence a SON 'original' generator in disguise), from about 20 years ago. The parallel sided part of the hubshell itself is steel, so acts as the field shunt. The rare-earth magnets are ~2mm thickness.

So based on other designs and the experiences reported in the link I posted above, I'd suggest that if you want to use modern magnets, ones of appropriate pole area and ~1.5 to ~2mm thickness ought to be a good starting point. The reason why there is likely to be commonality between designs (in this respect) is largely because the soft iron material in the claw poles will saturate at about the same field strength and this is a limiting factor in the design.

One note of caution though; in other pages on the site linked previously, there is a suggested design for a more complex backing ring/shunt for the magnets to be mounted on, including a suggestion that this could be made of aluminium. This is nonsense; the part has to be steel or iron because it shunts the magnetic field. Secondly if the magnets sit in pockets (rather than be separated by grooves) the field will be shunted at the sides and this will result in less field passing through the claw poles where you need it.

cheers

So based on other designs and the experiences reported in the link I posted above, I'd suggest that if you want to use modern magnets, ones of appropriate pole area and ~1.5 to ~2mm thickness ought to be a good starting point. The reason why there is likely to be commonality between designs (in this respect) is largely because the soft iron material in the claw poles will saturate at about the same field strength and this is a limiting factor in the design.

One note of caution though; in other pages on the site linked previously, there is a suggested design for a more complex backing ring/shunt for the magnets to be mounted on, including a suggestion that this could be made of aluminium. This is nonsense; the part has to be steel or iron because it shunts the magnetic field. Secondly if the magnets sit in pockets (rather than be separated by grooves) the field will be shunted at the sides and this will result in less field passing through the claw poles where you need it.

cheers

-------------------------------------------------------------------------------

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

Re: Sa ag/fg/gh6 dynohubs: why no modern magnet ring spares

Brucey wrote:... the ring doesn't need to have super magnetic properties because the field running through it doesn't change that much ...

... actually the magnetic field running through it is supposed to be totally STATIC since the ring is conceived to just magnetically close/short the North-South sequence of the magnets, nevertheless it must have good magnetic properties therefore maintaining a good magnetic field strength through the claws and in turn, finally, through the armature coil.

Re: Sa ag/fg/gh6 dynohubs: why no modern magnet ring spares

in practice the field in the backing ring is not exactly 100% static because the reluctance of the magnetic circuit does vary slightly. This is obvious, not least because because if there wasn't any such variation, there wouldn't be any 'cogging' (eg when the generator is turned by hand) in the generator either. However the fluctuations are comparatively small and the net losses to the generator are similarly small even if the ring is made from mild steel rather than a better soft magnet material.

The reason for the losses being small with a mild steel backing ring is because of the nature of minor hysteresis loops (on a B-H plot) in this material; major hysteresis loops (generated when H varies significantly) are large in area (incredibly lossy) but minor loops (arising from much smaller variations in H) enclose hardly any area by comparison; losses are similarly small.

It isn't difficult to determine these things, provided you have a drift-free integrating circuit and are prepared to wind the required search coils.

cheers

The reason for the losses being small with a mild steel backing ring is because of the nature of minor hysteresis loops (on a B-H plot) in this material; major hysteresis loops (generated when H varies significantly) are large in area (incredibly lossy) but minor loops (arising from much smaller variations in H) enclose hardly any area by comparison; losses are similarly small.

It isn't difficult to determine these things, provided you have a drift-free integrating circuit and are prepared to wind the required search coils.

cheers

-------------------------------------------------------------------------------

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

Re: Sa ag/fg/gh6 dynohubs: why no modern magnet ring spares

Brucey wrote:...

The reason why no-one offers a conversion kit is because there probably isn't any money in it. How much would you think such a kit would sell for?

cheers

I don,t know I wondered if there might be an economic way if doing it for the possible market size..

If not much magnetism is required compared to modern hubs , I thought this might allow cheaper methods, eg I once dismantled a Cibie dyno whose magnetpoles were made from a continuous ring of magnetic material. I

But what about a retaining ring , some magnets and some glue, and leave assembly to customer to save money.

------------You may not use this post in Cycle or other magazine ------

Re: Sa ag/fg/gh6 dynohubs: why no modern magnet ring spares

it is always going to be a bit of a DIY project...?.

Perhaps significantly it is also going to be a one-way street in most cases; unless you happen to have a keeper for the original magnet, it won't be going back on and doing anything useful.

cheers

Perhaps significantly it is also going to be a one-way street in most cases; unless you happen to have a keeper for the original magnet, it won't be going back on and doing anything useful.

cheers

-------------------------------------------------------------------------------

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

Re: Sa ag/fg/gh6 dynohubs: why no modern magnet ring spares

Brucey wrote:...the reluctance of the magnetic circuit does vary slightly ...

During the transition in the between reversing N/S polarity the circuit reluctance does vary a lot i think!

Re: Sa ag/fg/gh6 dynohubs: why no modern magnet ring spares

ConRAD wrote:Brucey wrote:...the reluctance of the magnetic circuit does vary slightly ...

During the transition in the between reversing N/S polarity the circuit reluctance does vary a lot i think!

In relation to the field value in the backing ring the magnitude of the reluctance is the value of interest. If the magnitude of the reluctance (rather than the vector value) stayed constant and the pole pieces were made in a 'perfect' soft magnetic material, there would be no 'cogging' when the generator is turned slowly by hand. However there is cogging, the magnitude of the reluctance does change and as a consequence there is a small variation in the field strength within the backing ring too, i.e. it isn't quite constant.

cheers

-------------------------------------------------------------------------------

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

Re: Sa ag/fg/gh6 dynohubs: why no modern magnet ring spares

Brucey wrote:... in relation to the field value in the backing ring the magnitude of the reluctance is the value of interest. If the magnitude of the reluctance (rather than the vector value) stayed constant and the pole pieces were made in a 'perfect' soft magnetic material, there would be no 'cogging' when the generator is turned slowly by hand. However there is cogging, the magnitude of the reluctance does change and as a consequence there is a small variation in the field strength within the backing ring too, i.e. it isn't quite constant ...

During hub rotation the overall magnetic circuit reluctance varies a lot, its value basically depending on the instantaneous air gap in the between the static (armature coil) and the rotating part (magnets) of hub generator. Inside the backing ring the reluctance is "almost" zero and the strength of the magnetic field is virtually constant. The "cogging" perception when the generator is turned slowly by hand is basically due to the alternate attraction between rotor and stator due to this cyclically variable reluctance and associated variable induced field [B].

Re: Sa ag/fg/gh6 dynohubs: why no modern magnet ring spares

ConRAD wrote:...During hub rotation the overall magnetic circuit reluctance varies a lot, its value basically depending on the instantaneous air gap in the between the static (armature coil) and the rotating part (magnets) of hub generator....

with better design (eg tapered pole pieces) the reluctance could be made to be more constant than it usually is.

Inside the backing ring the reluctance is "almost" zero and the strength of the magnetic field is virtually constant. The "cogging" perception when the generator is turned slowly by hand is basically due to the alternate attraction between rotor and stator due to this cyclically variable reluctance and associated variable induced field [B].

well yes, but you can can't have an arrangement of this sort (with variable reluctance) in which the field in the backing ring remains constant. Not possible. 'Virtually constant' is not correct. The variations are however small enough that the use of a non-optimised magnetic material in this part does not create substantial problems. Which was my point.

Note that this is largely because of the magnetic properties of cheap steels that you might use, rather than the constancy of the field per se.

cheers

-------------------------------------------------------------------------------

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

Re: Sa ag/fg/gh6 dynohubs: why no modern magnet ring spares

All this talk of reluctance explains why I opted for mechanical engineering.

The photo brucey posted at the top of the thread suggests that it should be straightforward to put the sturmey magnet ring in a lathe and skim off sufficient material to enable 20 neodymium magnets to be araldited in place. What do you all think.

The photo brucey posted at the top of the thread suggests that it should be straightforward to put the sturmey magnet ring in a lathe and skim off sufficient material to enable 20 neodymium magnets to be araldited in place. What do you all think.

At the last count:- Peugeot 531 pro, Dawes Discovery Tandem, Dawes Kingpin X3, Raleigh 20 stowaway X2, 1965 Moulton deluxe, Falcon K2 MTB dropped bar tourer, Rudge Bi frame folder, Longstaff trike conversion on a Giant XTC 840

Re: Sa ag/fg/gh6 dynohubs: why no modern magnet ring spares

rjb wrote:All this talk of reluctance explains why I opted for mechanical engineering.

The photo brucey posted at the top of the thread suggests that it should be straightforward to put the sturmey magnet ring in a lathe and skim off sufficient material to enable 20 neodymium magnets to be araldited in place. What do you all think.

I think that would work, but the magnet material(s) they used are notoriously brittle; chipped corners are not uncommon, and I've seen several which have cracked, apparently in normal service. I have not tried it but it might be more difficult to machine than you may expect.

FWIW the whole arrangement could be made more secure by using spacers bonded between the magnets. However they don't appear to need this in modern designs.

I suspect a reasonable -not to mention lighter weight- home-made backing ring could be manufactured by using a hardwood ring (set into the dust shield), into which a thinner mild steel ring (eg made from flat stock) is set. This can be trued up 'in situ' if necessary, before the magnets are bonded into position. The mild steel ring need only be about 2.5-3mm thickness and it would be thick enough for the field strengths envisaged.

cheers

-------------------------------------------------------------------------------

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~