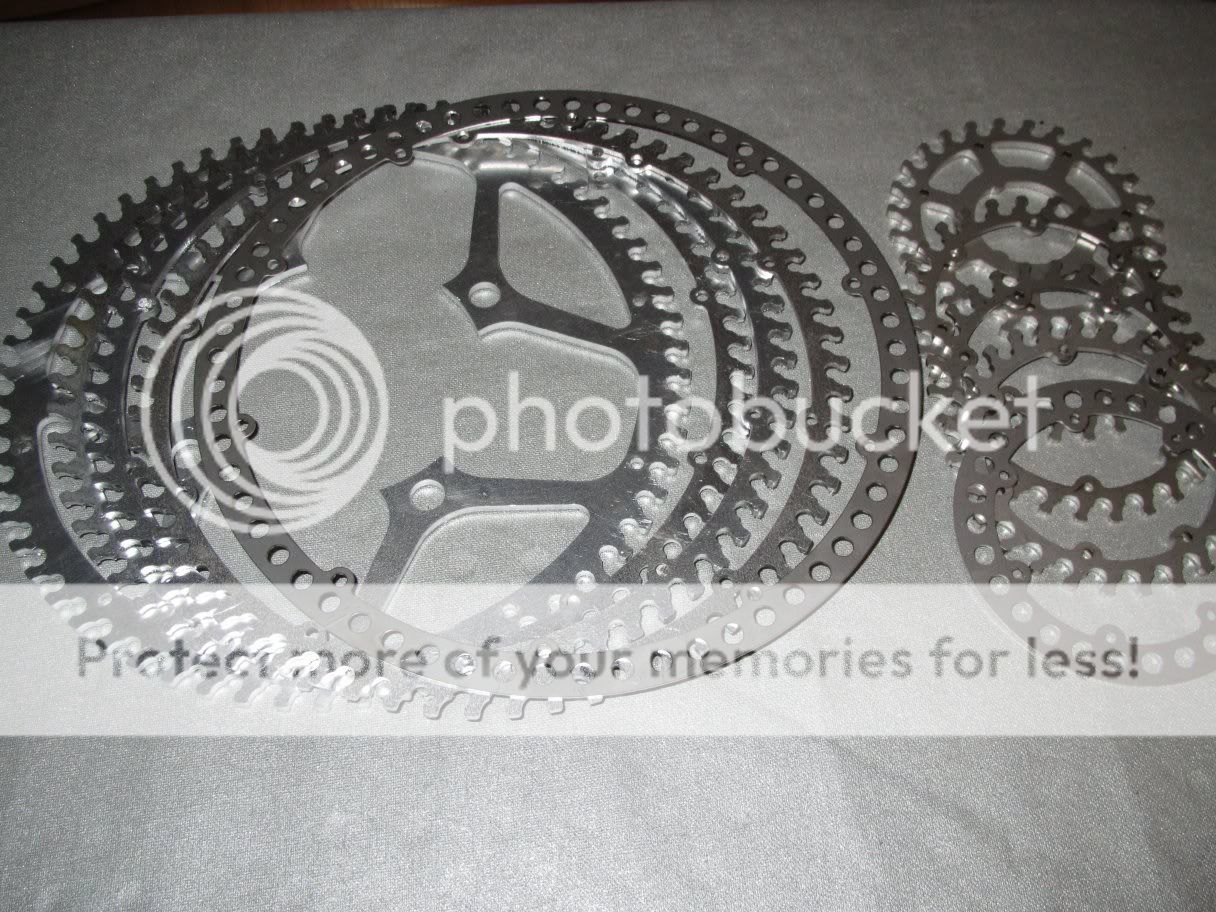

I made my own pulleys for the belt from laser cut lamination stacks. This actually held costs down a bit (the laminations cost me £40 in total) though the belt itself was very expensive (£76).

Here's a picture of the bike when it was nearly done.

I've put 150 miles on it in the last 2 weeks and the bike is better than I could have hoped. The IGH with versa drop 'sti' shifter works well and the belt drive delivers a magic carpet ride. The bike is SILENT in a way that's new to me (all you hear is the front tyre on the road) on other bikes I can always hear the chain/deraillieur. And it feels more efficient than my previous alfine 8 IGH bike (i.e. I pull a higher gear everywhere & average a higher speed).

If anyone wants to do something similar, all the design information is on endless sphere -

http://endless-sphere.com/forums/viewto ... &start=165

Using a laminate stack for the pulleys means you can get the belt line perfect with very little effort.