Sturmey NIG 3s hub; what to look out for, what breaks.

Sturmey NIG 3s hub; what to look out for, what breaks.

When Sturmey Archer closed its doors in Nottingham most people with any involvement in cycling felt that something important had been lost. The good stuff, both in plant and designs, became the property of SunRace Sturmey Archer. They were meant to resume manufacturing of SA products in Taiwan, but few held their breath in anticipation. Others rubbed their hands with glee; whilst SA were not building hubs, others (shimano and SRAM) were happily making hubs to fill the gap in the market. It is no accident that SRAM enjoyed some high production numbers and good profits around this time.

However in due course hubs did start to appear from Taiwan. [They arguably 'bought market share back' with low prices; you could say this eventually worked; SRAM closed their european IGH manufacturing facility (formerly Fichtel und Sachs) about ten years ago and relocated to Taiwan. That didn't work out for them and they abandoned IGH production altogether about two years ago.] Some SunRace-SA designs were little changed from those made in Nottingham, others were new or revised. By far their biggest selling hub, the AW, reappeared in due course, and it is this hub/internal design which this post mainly concerns.

When the AW reappeared it was initially known as 'AW3' and even had a chrome-plated steel shell, like the Nottingham built models. However the old (pre-NIG) AW internal was gone, replaced by a revised hub having NIG functionality, but retaining the toggle chain control and hubshell style of the pre-NIG model. Thus the NIG-AW came to widespread attention for the first time.

Since 2002 the NIG-AW internal has appeared in a wide range of hubs such as AW3, AW, SRF3, BSR (Brompton) amongst others. With a shorter planet cage it is found in hubs such as X-RD3. It also forms the basis for many of the parts in the Brompton BWR hub. Many people think that this hub design originated in Taiwan. However this is far from being the case.

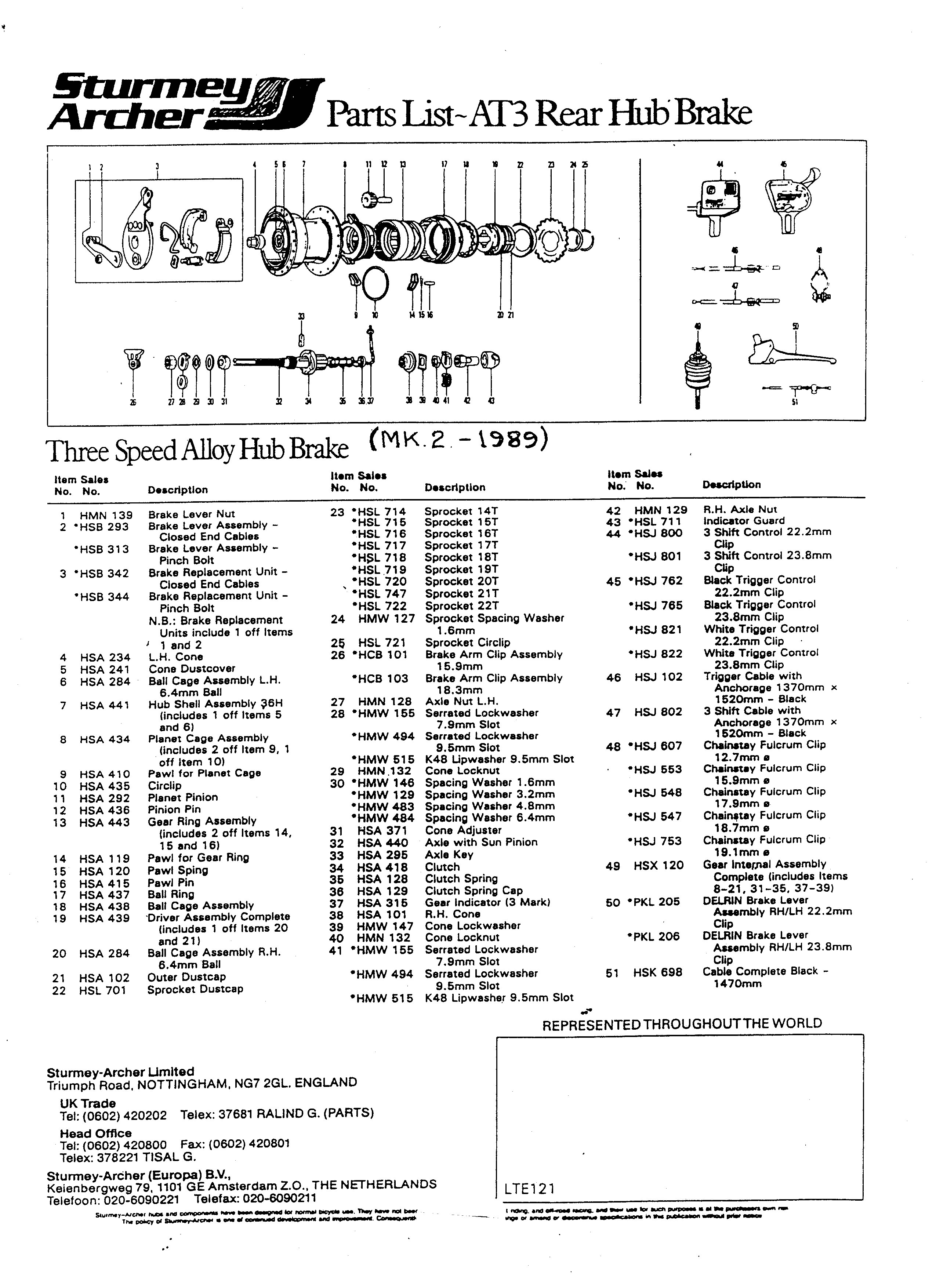

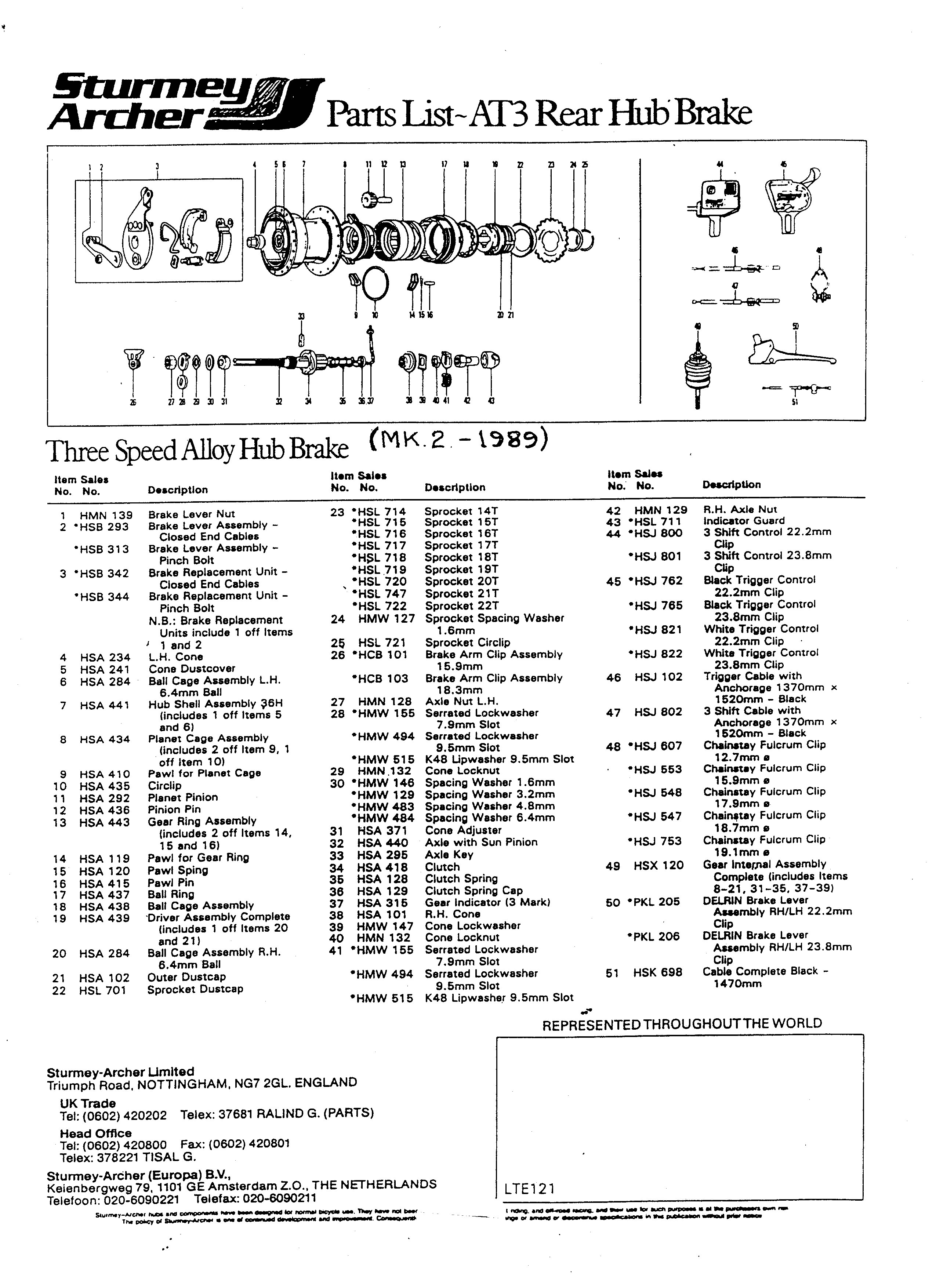

SA have made NIG hubs of various kinds since ~1983. The current designs for the NIG-AW driver, actuator plate, sliding clutch spline, ring bearing, dustcaps, sprocket fitments etc originated with (or before) the AT3 model in 1989 and were also used in the ill-fated 5-star model of ~1991. These designs are shared with all single-toggle 5s models from 1993 to 2016. The NIG driver was used in several 3s brake hubs (mainly for export) in the late 1990s, including steelite 3s and ABC (90mm brake 3s) models. However these brake hubs turned out to be very unreliable, with weakened sun pinions, and cantilevered planet pinions, amongst other things.

These problems were addressed by a redesign which appeared as the Summit X-RD3 model in 2000, and used many of the parts seen in the AT3 model from 1989, including the driver and axle.

You can see the current (dated 2014) SRF3 parts here

http://www.sturmey-archer.com/files/catalog/files/311/PART%20LIST%20-%20AW%20SRF3.pdf

and the Summit X-RD3 parts (dated 2000) here (p8)

http://www.sturmey-archerheritage.com/files/view-286.pdf

You can see that the internals are essentially the same thing; the ball ring has a different part number (it has a different offset I think) and the planet cage is a different length because it is a brake hub, but that is about it.

However between design and manufacturing changes, the NIG-AW design has been (and is) imperfect.

In part 2 I will give some examples of NIG-AW foibles.

However in due course hubs did start to appear from Taiwan. [They arguably 'bought market share back' with low prices; you could say this eventually worked; SRAM closed their european IGH manufacturing facility (formerly Fichtel und Sachs) about ten years ago and relocated to Taiwan. That didn't work out for them and they abandoned IGH production altogether about two years ago.] Some SunRace-SA designs were little changed from those made in Nottingham, others were new or revised. By far their biggest selling hub, the AW, reappeared in due course, and it is this hub/internal design which this post mainly concerns.

When the AW reappeared it was initially known as 'AW3' and even had a chrome-plated steel shell, like the Nottingham built models. However the old (pre-NIG) AW internal was gone, replaced by a revised hub having NIG functionality, but retaining the toggle chain control and hubshell style of the pre-NIG model. Thus the NIG-AW came to widespread attention for the first time.

Since 2002 the NIG-AW internal has appeared in a wide range of hubs such as AW3, AW, SRF3, BSR (Brompton) amongst others. With a shorter planet cage it is found in hubs such as X-RD3. It also forms the basis for many of the parts in the Brompton BWR hub. Many people think that this hub design originated in Taiwan. However this is far from being the case.

SA have made NIG hubs of various kinds since ~1983. The current designs for the NIG-AW driver, actuator plate, sliding clutch spline, ring bearing, dustcaps, sprocket fitments etc originated with (or before) the AT3 model in 1989 and were also used in the ill-fated 5-star model of ~1991. These designs are shared with all single-toggle 5s models from 1993 to 2016. The NIG driver was used in several 3s brake hubs (mainly for export) in the late 1990s, including steelite 3s and ABC (90mm brake 3s) models. However these brake hubs turned out to be very unreliable, with weakened sun pinions, and cantilevered planet pinions, amongst other things.

These problems were addressed by a redesign which appeared as the Summit X-RD3 model in 2000, and used many of the parts seen in the AT3 model from 1989, including the driver and axle.

You can see the current (dated 2014) SRF3 parts here

http://www.sturmey-archer.com/files/catalog/files/311/PART%20LIST%20-%20AW%20SRF3.pdf

and the Summit X-RD3 parts (dated 2000) here (p8)

http://www.sturmey-archerheritage.com/files/view-286.pdf

You can see that the internals are essentially the same thing; the ball ring has a different part number (it has a different offset I think) and the planet cage is a different length because it is a brake hub, but that is about it.

However between design and manufacturing changes, the NIG-AW design has been (and is) imperfect.

In part 2 I will give some examples of NIG-AW foibles.

Last edited by Brucey on 17 Mar 2020, 8:59pm, edited 4 times in total.

-------------------------------------------------------------------------------

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

Re: Sturmey NIG 3s hub; what to look out, what breaks.

part 2; what changed, and some of what breaks.

The NIG-AW design is clearly based on the old pre-NIG-AW design but nearly everything is different. Key differences include

a) that the driver drives the ring gear via extra pawls (in gears 1 and 2) or drives the planet cage via a sliding clutch (gear 3).

b) the sliding clutch fits to an internal spline on the driver

c) the sliding clutch defeats the high gear drive pawls in gear 1, much as the cruciform clutch does in a pre-NIG AW.

d) Because the driver/clutch assy is longer than the old pre NIG design, the sun pinion is set further to the left, the ring gear is longer, and the planet cage is made shorter.

e) there is no 'carrier' for the sliding clutch key; spring loads cause parasitic friction on the clutch key in gears 2 and 1.

f) there is no carrier for the clutch spring to bear against; so there are further (small) parasitic losses in the hub because of this

g)the planet pinions are slightly narrower width than pre-NIG designs

h) the planet pinions are invariably a sloppier fit on the planet pinion pins

i) the sun pinion is integrated into the axle, rather that riveted onto it

j) the planet cage is a simplified and lightened part, using different pawls for the low gear drive to the hubshell.

k) because both the driver and the planet cage are 'in mesh'/engaged in gear 3, wheeling the bike backwards could cause the hub to see abnormal loads, because the driver is turned backwards faster than the planet cage. There is therefore an 'actuator plate' fitted, whose sole purpose is to ensure the driver pawls are retracted whenever the driver/sliding clutch turns 'forward' (or backwards less fast in fact) vs the driver/ ring gear.

Some of these things are hangovers from the NIG driver design (going all the way back to the 5-star hub), some are for cost saving, and a few might be improvements over older designs. After nearly twenty years the dust has settled and we mostly know what to look out for.

' What breaks' is on the face of it quite a long list. However the most likely breakages are easily avoided and/or easily repaired. Catastrophic (ride stopping) failures are rare; also you can still buy most small SA internal parts and repairs are not difficult to do.

1) High gear drive pawls. In NIG-AW they seem more likely to chip and be damaged than in previous designs. They see load in gears 2 and 3. Part of the problem is that they engage (and have done since about 1986) onto a twenty-tooth dog ring, rather than the original 10T dog ring. There's half as much backlash with the 20T dog ring, but at least twice the chance of one-pawl drive attempts, which always end with slippage and the possibility of damage. I say 'at least' because the NIG ring gear is usually a sloppier fit in the dog ring, further increasing the chances of one-pawl drive.

2) High gear drive pawls. The NIG design tolerates gear maladjustment right up until the high gear drive pawls start engaging/slipping in gear 1/2 because they are partly retracted. Slippage under load means the high gear drive pawls are soon damaged to the point that the hub will stop working. Between both the things above, I have seen multiple examples of broken high gear drive pawls.

3) RH hub bearing cone worn out. This often happens because the locking washer that retains the RH cone has been deleted after a certain date. This means the RH cone will , if it comes loose (which it can and does do), precess into the hub and destroy itself. If the damage is bad enough it also destroys the driver where the hub bearings run against it. I have seen multiple examples of this fault.

4) Actuator plate failure. it isn't clear whether they crack (on the folded corners) or simply fall off the driver first. In any event they are a very loose fit in many cases and can obviously come off quite easily. It usually isn't possible to tell exactly what happened after the event because you just have a hub full of shrapnel to look at. If this failure is caught early enough, there is usually minimal collateral damage in the rest of the hub. However if the signs of failure ( baulky downshifts, funny noises etc) are ignored, serious hub damage can be caused; instead of a £1.50 spare part you might end up needing a new hub. I have seen dozens of actuator plate failures.

5) Stripped sun pinion. The NIG axle ought to be stronger with its integrated sun pinion. However a small number of axles have been found with the sun pinion teeth completely worn off, in fairly low mileage hubs. In such hubs the planet gears (which run against the sun pinion) are most often practically unmarked. Since pre-NIG AWs seem virtually immune from similar problems despite (in some instances) even an almost total absence of lubricant, the conclusion is that the NIG sun pinion is most probably not adequately hardened in such cases. I've seen a handful of examples of this; between myself and two or three others, about a dozen in total.

6) Crumbling axle threads. Occasionally I have seen axle threads which appear not to have been correctly hardened. The result is that the threads can (usually on the ends of the axle where the track nuts go) crumble away, rendering the axle useless. I have seen a handful of such cases.

7) damaged axle. The clutch spring bears against the sliding clutch (instead of a static carrier as per the old AW design) and should turn with it, such that the plastic spring cap spins against the end of the RH cone. However if the spring deforms unevenly, it rubs/binds against the axle instead, and can start to spin against the clutch itself. This can damage the axle, clutch and spring, with little outward sign that there is anything amiss to begin with. Clutch springs in SA hubs are variously wound CW or ACW; it usually makes no difference but in this application it might do, so be sure that any replacement has the correct handedness.

8 ) damaged axle key/control rod. The NIG axle key is square (cf the old AW's round key) and should have more threads in the tapped hole. However the fit of some rods in some holes is substandard and the result can be that the control rod just pulls out of the hub. This normally means a new control rod and/or key is required.

9) Worn axle key. The sliding clutch rubs against the axle key under spring pressure (or more during clumsy shifts) so wears on the ends. It is rare that this causes any real problem.

10) Lost axle key. If the control rod is removed when gear 3 is not fully engaged (i.e. so that the sliding clutch hasn't gone fully leftwards and is still sat on top of the planet pinion pins), the axle key can turn so that it no longer presents itself to the control rod when the control rod is refitted. Early NIG hubs often have slightly shorter axle keys (by about 0.2mm typically) and these do seem to get out of position more easily.

11) Bad lubrication. SA use a thinnish grease in their hubs. This is OK but it doesn't either move around inside the hub or stay where it should and it also doesn't have really good anti-corrosion properties. In a hub that is a few years old, the grease is usually to be found to have gathered in places where it cannot possibly do any good whatsoever, and the wearing parts (bearings and gear teeth) can be practically bone-dry. I suspect that if some 'stringing' additives were used in the grease it would stay put better.

When the production was resumed in Taiwan, there were QA problems to start with, and the design changes to the hubs meant different, and ongoing problems that hadn't been seen before. One long-standing LBS owner told me recently that in thirty years of selling Nottingham-built AW hubs (totalling thousands probably) he only ever had one hub that had to go back under warranty; the ball ring had stripped the threads in the hubshell, presumably due to bad tolerances. However his first batch of about 100 or so bikes with Taiwan built AW3 hubs was completely different. It is estimated that about eighty of them suffered failed actuator plates and about five had stripped sun pinions, within about two years. Coincidentally or not, the manufacturer of those bikes went under not long afterwards. This episode cost the LBS about three man-weeks of labour to sort out and to say he was not a happy bunny was the understatement of all time; still pretty angry about it over fifteen years later.

The NIG-AW design is clearly based on the old pre-NIG-AW design but nearly everything is different. Key differences include

a) that the driver drives the ring gear via extra pawls (in gears 1 and 2) or drives the planet cage via a sliding clutch (gear 3).

b) the sliding clutch fits to an internal spline on the driver

c) the sliding clutch defeats the high gear drive pawls in gear 1, much as the cruciform clutch does in a pre-NIG AW.

d) Because the driver/clutch assy is longer than the old pre NIG design, the sun pinion is set further to the left, the ring gear is longer, and the planet cage is made shorter.

e) there is no 'carrier' for the sliding clutch key; spring loads cause parasitic friction on the clutch key in gears 2 and 1.

f) there is no carrier for the clutch spring to bear against; so there are further (small) parasitic losses in the hub because of this

g)the planet pinions are slightly narrower width than pre-NIG designs

h) the planet pinions are invariably a sloppier fit on the planet pinion pins

i) the sun pinion is integrated into the axle, rather that riveted onto it

j) the planet cage is a simplified and lightened part, using different pawls for the low gear drive to the hubshell.

k) because both the driver and the planet cage are 'in mesh'/engaged in gear 3, wheeling the bike backwards could cause the hub to see abnormal loads, because the driver is turned backwards faster than the planet cage. There is therefore an 'actuator plate' fitted, whose sole purpose is to ensure the driver pawls are retracted whenever the driver/sliding clutch turns 'forward' (or backwards less fast in fact) vs the driver/ ring gear.

Some of these things are hangovers from the NIG driver design (going all the way back to the 5-star hub), some are for cost saving, and a few might be improvements over older designs. After nearly twenty years the dust has settled and we mostly know what to look out for.

' What breaks' is on the face of it quite a long list. However the most likely breakages are easily avoided and/or easily repaired. Catastrophic (ride stopping) failures are rare; also you can still buy most small SA internal parts and repairs are not difficult to do.

1) High gear drive pawls. In NIG-AW they seem more likely to chip and be damaged than in previous designs. They see load in gears 2 and 3. Part of the problem is that they engage (and have done since about 1986) onto a twenty-tooth dog ring, rather than the original 10T dog ring. There's half as much backlash with the 20T dog ring, but at least twice the chance of one-pawl drive attempts, which always end with slippage and the possibility of damage. I say 'at least' because the NIG ring gear is usually a sloppier fit in the dog ring, further increasing the chances of one-pawl drive.

2) High gear drive pawls. The NIG design tolerates gear maladjustment right up until the high gear drive pawls start engaging/slipping in gear 1/2 because they are partly retracted. Slippage under load means the high gear drive pawls are soon damaged to the point that the hub will stop working. Between both the things above, I have seen multiple examples of broken high gear drive pawls.

3) RH hub bearing cone worn out. This often happens because the locking washer that retains the RH cone has been deleted after a certain date. This means the RH cone will , if it comes loose (which it can and does do), precess into the hub and destroy itself. If the damage is bad enough it also destroys the driver where the hub bearings run against it. I have seen multiple examples of this fault.

4) Actuator plate failure. it isn't clear whether they crack (on the folded corners) or simply fall off the driver first. In any event they are a very loose fit in many cases and can obviously come off quite easily. It usually isn't possible to tell exactly what happened after the event because you just have a hub full of shrapnel to look at. If this failure is caught early enough, there is usually minimal collateral damage in the rest of the hub. However if the signs of failure ( baulky downshifts, funny noises etc) are ignored, serious hub damage can be caused; instead of a £1.50 spare part you might end up needing a new hub. I have seen dozens of actuator plate failures.

5) Stripped sun pinion. The NIG axle ought to be stronger with its integrated sun pinion. However a small number of axles have been found with the sun pinion teeth completely worn off, in fairly low mileage hubs. In such hubs the planet gears (which run against the sun pinion) are most often practically unmarked. Since pre-NIG AWs seem virtually immune from similar problems despite (in some instances) even an almost total absence of lubricant, the conclusion is that the NIG sun pinion is most probably not adequately hardened in such cases. I've seen a handful of examples of this; between myself and two or three others, about a dozen in total.

6) Crumbling axle threads. Occasionally I have seen axle threads which appear not to have been correctly hardened. The result is that the threads can (usually on the ends of the axle where the track nuts go) crumble away, rendering the axle useless. I have seen a handful of such cases.

7) damaged axle. The clutch spring bears against the sliding clutch (instead of a static carrier as per the old AW design) and should turn with it, such that the plastic spring cap spins against the end of the RH cone. However if the spring deforms unevenly, it rubs/binds against the axle instead, and can start to spin against the clutch itself. This can damage the axle, clutch and spring, with little outward sign that there is anything amiss to begin with. Clutch springs in SA hubs are variously wound CW or ACW; it usually makes no difference but in this application it might do, so be sure that any replacement has the correct handedness.

8 ) damaged axle key/control rod. The NIG axle key is square (cf the old AW's round key) and should have more threads in the tapped hole. However the fit of some rods in some holes is substandard and the result can be that the control rod just pulls out of the hub. This normally means a new control rod and/or key is required.

9) Worn axle key. The sliding clutch rubs against the axle key under spring pressure (or more during clumsy shifts) so wears on the ends. It is rare that this causes any real problem.

10) Lost axle key. If the control rod is removed when gear 3 is not fully engaged (i.e. so that the sliding clutch hasn't gone fully leftwards and is still sat on top of the planet pinion pins), the axle key can turn so that it no longer presents itself to the control rod when the control rod is refitted. Early NIG hubs often have slightly shorter axle keys (by about 0.2mm typically) and these do seem to get out of position more easily.

11) Bad lubrication. SA use a thinnish grease in their hubs. This is OK but it doesn't either move around inside the hub or stay where it should and it also doesn't have really good anti-corrosion properties. In a hub that is a few years old, the grease is usually to be found to have gathered in places where it cannot possibly do any good whatsoever, and the wearing parts (bearings and gear teeth) can be practically bone-dry. I suspect that if some 'stringing' additives were used in the grease it would stay put better.

When the production was resumed in Taiwan, there were QA problems to start with, and the design changes to the hubs meant different, and ongoing problems that hadn't been seen before. One long-standing LBS owner told me recently that in thirty years of selling Nottingham-built AW hubs (totalling thousands probably) he only ever had one hub that had to go back under warranty; the ball ring had stripped the threads in the hubshell, presumably due to bad tolerances. However his first batch of about 100 or so bikes with Taiwan built AW3 hubs was completely different. It is estimated that about eighty of them suffered failed actuator plates and about five had stripped sun pinions, within about two years. Coincidentally or not, the manufacturer of those bikes went under not long afterwards. This episode cost the LBS about three man-weeks of labour to sort out and to say he was not a happy bunny was the understatement of all time; still pretty angry about it over fifteen years later.

Last edited by Brucey on 16 Mar 2020, 10:58pm, edited 14 times in total.

-------------------------------------------------------------------------------

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

Re: Sturmey NIG 3s hub; what to look out, what breaks.

part 3: how to live with it.

In reference to the previous post;

1), 2). Keep the hub adjusted properly is the main thing to avoid problems of this sort. Once in every ten or twenty or so shifts from gear 1 to gear 2 [edit or indeed a resumption of pedalling following freewheeling, occasionally) there will likely be a one-pawl drive attempt, and the hub will slip slightly after two turns or so on the pedals. If you develop the habit of not pedalling forcefully for a couple of pedal turns after a shift/resumption, this slippage, should it occur, won't do any damage.

3) Obtain and fit lockwasher part HMW147. Fit it with the LH cone backed off, respecting the internal clearance that is set by unscrewing the RH cone 1/2 turn from full tight.

4) Buy a spare actuator plate and (if nothing else) remove the driver from the hub and check/adjust the fit of the old one. Ideally the actuator plate shouldn't be either noticeably loose or at all draggy when turned on the driver. It certainly shouldn't come on and off the driver without any real struggle. The fit can be adjusted using a small adjustable spanner to slightly reset the bends in the actuator plate.

5) Keep the hub well lubricated and about once a year check the sun pinion for wear. Because you can wangle the axle key out of the axle without removing the ball ring from the hub, the axle can usually be withdrawn (far enough for the sun pinion to be seen ) on the LH side of the hub.

6) it will be obvious if this occurs

7) be prepared to change the spring if required (*)

8 ) check the fit of the control rod in the axle key when the opportunity presents itself. You should be shooting for a male thread at least 0.2mm larger diameter than the female hole it screws into

11) use oil or a better (more fluid) SFG inside the hub, e.g. introduced via the hollow axle using a syringe, or directly when inspecting internal parts.

[(*) Edit: It isn't a bad idea, when servicing the hub, to assemble the axle so that the axle key, control rod, sliding clutch, spring, and RH cone are in their usual positions in/on the axle. You will be able to see if the spring is likely to bind against the axle when compressed or not.]

in addition to the above using a washer that fits the flats on the axle is often possible (unless the OLN is set very short with a long axle) on the left side of the hub; this usually eases LH cone adjustment, since you won't have to use two spanners.

This all sounds like a lot but in actual fact most of it will take about an hour the first time and about the same per year thereafter; a cheap price to pay for the simplicity and weatherproofness etc of the hub gear, I'd say.

Despite the possible problems outlined above, the SA NIG-AW 3s hub is still the best bet of currently available 3s hubs; after all the SRAM 3s hub is no longer made and is no great loss; the final version was a horrible thing. The shimano Nexus 3s hub is competent enough but it too tends to wear out and break. It also comes with a steel shell only so doesn't build into good wheels as easily.

Other alternatives include the rotary shifted SA hub (which I've had little experience of) and the old pre-NIG AW. The latter internal has very low parasitic losses, accepts two sprockets without difficulty (the driver splines are longer), fits into a modern SRF3 hubshell, and can be fitted with an inherently stronger axle; it thus might be the thinking man's choice of three speed hub, provided a 162.7mm axle is long enough.

cheers

In reference to the previous post;

1), 2). Keep the hub adjusted properly is the main thing to avoid problems of this sort. Once in every ten or twenty or so shifts from gear 1 to gear 2 [edit or indeed a resumption of pedalling following freewheeling, occasionally) there will likely be a one-pawl drive attempt, and the hub will slip slightly after two turns or so on the pedals. If you develop the habit of not pedalling forcefully for a couple of pedal turns after a shift/resumption, this slippage, should it occur, won't do any damage.

3) Obtain and fit lockwasher part HMW147. Fit it with the LH cone backed off, respecting the internal clearance that is set by unscrewing the RH cone 1/2 turn from full tight.

4) Buy a spare actuator plate and (if nothing else) remove the driver from the hub and check/adjust the fit of the old one. Ideally the actuator plate shouldn't be either noticeably loose or at all draggy when turned on the driver. It certainly shouldn't come on and off the driver without any real struggle. The fit can be adjusted using a small adjustable spanner to slightly reset the bends in the actuator plate.

5) Keep the hub well lubricated and about once a year check the sun pinion for wear. Because you can wangle the axle key out of the axle without removing the ball ring from the hub, the axle can usually be withdrawn (far enough for the sun pinion to be seen ) on the LH side of the hub.

6) it will be obvious if this occurs

7) be prepared to change the spring if required (*)

8 ) check the fit of the control rod in the axle key when the opportunity presents itself. You should be shooting for a male thread at least 0.2mm larger diameter than the female hole it screws into

11) use oil or a better (more fluid) SFG inside the hub, e.g. introduced via the hollow axle using a syringe, or directly when inspecting internal parts.

[(*) Edit: It isn't a bad idea, when servicing the hub, to assemble the axle so that the axle key, control rod, sliding clutch, spring, and RH cone are in their usual positions in/on the axle. You will be able to see if the spring is likely to bind against the axle when compressed or not.]

in addition to the above using a washer that fits the flats on the axle is often possible (unless the OLN is set very short with a long axle) on the left side of the hub; this usually eases LH cone adjustment, since you won't have to use two spanners.

This all sounds like a lot but in actual fact most of it will take about an hour the first time and about the same per year thereafter; a cheap price to pay for the simplicity and weatherproofness etc of the hub gear, I'd say.

Despite the possible problems outlined above, the SA NIG-AW 3s hub is still the best bet of currently available 3s hubs; after all the SRAM 3s hub is no longer made and is no great loss; the final version was a horrible thing. The shimano Nexus 3s hub is competent enough but it too tends to wear out and break. It also comes with a steel shell only so doesn't build into good wheels as easily.

Other alternatives include the rotary shifted SA hub (which I've had little experience of) and the old pre-NIG AW. The latter internal has very low parasitic losses, accepts two sprockets without difficulty (the driver splines are longer), fits into a modern SRF3 hubshell, and can be fitted with an inherently stronger axle; it thus might be the thinking man's choice of three speed hub, provided a 162.7mm axle is long enough.

cheers

Last edited by Brucey on 17 Mar 2020, 6:29pm, edited 2 times in total.

-------------------------------------------------------------------------------

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

Re: Sturmey NIG 3s hub; what to look out for, what breaks.

A top job there Sir. Copied and saved....Thank you.

Re: Sturmey NIG 3s hub; what to look out for, what breaks.

a couple of further points concerning 1990s NIG-3s brake hubs and actuator plates;

1) The (inherently unreliable IMHO) 1990s NIG-3s brake hubs are recognisable by their cantilevered planet pinions. Many have a distinctive 'maltese cross' shaped spacer set to the right of the planet pinions, but I believe this was deleted in later versions of the hub since it served no real purpose, not in a hub with an axle that broke so easily. The axles can break but most likely fail by the sun pinion splitting.

[In any pre-NIG AW based hub there is a chance that (normally after many years of use) the sun pinion rivet will loosen and/or the sun pinion will split, or the axle will break through the rivet hole. Hence the 'all solid' axle HSA370 HSA107 ought to be an improvement in a pre-NIG AW.]

However in most cases the 1990s NIG-3s brake hub was fitted with a riveted sun pinion where the rivet went through a slot rather than a hole; this arrangement possesses a small fraction of the strength and is almost certain to fail even with a rider of modest strength pushing on the pedals.

A failed 1990s NIG-3s brake hub can be resuscitated in two ways;

a) there is an 'all solid' version of the riveted sun pinion axle. This still isn't ideal because (of necessity bearing in mind the axle it replaces) it has somewhat sharp corners which might lead the axle eventually suffering fatigue in bending. The part number is HSA571 and it replaces HSA534. It also retains the inherently less satisfactory cantilevered planet pinions.

b) it is possible to replace both the axle and the planet cage assembly with those from the 2000 onwards X-RD3. This costs a little more but is a better repair.

There is (I think) a similar story concerning the equivalent NIG-3s coaster brake hubs ( eg AWC models with different axle PNs) but I don't know the details.

2) Actuator plates were of course used on all 5s hubs (post S5-2, i.e. 1991 onwards). In this use they didn't seem to manifest an unusually high failure rate. Cynics might argue that these hubs were liable to break some other way first, and this masked the actuator plate weakness, but I think the true answer is a little more nuanced than that. In particular the highest loads on the actuator plate 'ears' only appear when wheeling the bike backwards and/or backpedalling, and indeed can only appear if the sliding clutch is able to transfer a reverse load through the planet cage. The sliding clutch is ramped where it engages with the planet cage, so it cannot transfer high reverse torque loads without become disengaged, provided it is still free to slide within the driver spline. Once under torque load however, the sliding is inhibited, so the sliding clutch can become jammed, but this doesn't always happen.

If you backpedal a NIG-AW in gear 3, it will either backpedal fairly quietly with a little more resistance than normal (which means the actuator plate/driver freewheel pawl mechanism is working as intended) or it will backpedal rather noisily, with a regular clunking sound, corresponding with visible spasms of slackness in the control toggle. The latter means the sliding clutch is lifting on the reverse torque ramps and it is this which is allowing the backpedalling to occur. [Some folk have run NIG-3s hubs without the actuator plate fitted; I have not done this but if you then wheel the bike backwards you are 100% reliant on the sliding clutch lifting on the reverse ramps; if this doesn't happen the hub will break. Also note that if you remove the actuator plate on a coaster brake hub, or the actuator plate is damaged, probably the brake won't work and/or the hub will break instantly]

I think the big difference between the NIG-5s hubs and the NIG-AW is that the 5s sliding clutches have shallower engagement and have more sloping reverse torque ramps; I think this means that the sliding clutch is more likely to lift away from the planet cage and the actuator plate is less likely to see the highest loads. The other thing is that the sun pinions in a 5s hub are (weakly) spring loaded so there is always a small drag force on the planet cage; this means that the sliding clutch is almost certain to rotate backwards (at least as far as the start of the reverse torque ramps) at an early stage, and this presumably also makes it more likely to then lift.

A simple way of giving the actuator plate an easier life is to

a) not backpedal during gearshifts (IMHO it is almost invariably best to carry on pedalling forwards during shifts in most SA hubs, but without any force applied) and/or

b) try and avoid wheeling the bike backwards, or at least ensure that the pedals are entirely free to turn backwards should you do so. On a large wheeled machine, if you feel any resistance from the hub when wheeling the bike backwards, and the pedals cannot turn (eg because a stand is still down or your leg/a bike is in the way) it is likely that the actuator plate is starting to deform and jam (much as the deformed one in the photo upthread). A deformed actuator plate is very likely to break before too much longer, not least because the deformation may inhibit the driver from ever turning backwards inside the ring gear.

It is easy enough to avoid wheeling the bike backwards on an unladen solo. But a heavy rear loaded bike is very likely to be wheeled backwards (e.g. out of a bike stand/rack/parking) and this is more likely to load the actuator plate up.

cheers

1) The (inherently unreliable IMHO) 1990s NIG-3s brake hubs are recognisable by their cantilevered planet pinions. Many have a distinctive 'maltese cross' shaped spacer set to the right of the planet pinions, but I believe this was deleted in later versions of the hub since it served no real purpose, not in a hub with an axle that broke so easily. The axles can break but most likely fail by the sun pinion splitting.

[In any pre-NIG AW based hub there is a chance that (normally after many years of use) the sun pinion rivet will loosen and/or the sun pinion will split, or the axle will break through the rivet hole. Hence the 'all solid' axle HSA370 HSA107 ought to be an improvement in a pre-NIG AW.]

However in most cases the 1990s NIG-3s brake hub was fitted with a riveted sun pinion where the rivet went through a slot rather than a hole; this arrangement possesses a small fraction of the strength and is almost certain to fail even with a rider of modest strength pushing on the pedals.

A failed 1990s NIG-3s brake hub can be resuscitated in two ways;

a) there is an 'all solid' version of the riveted sun pinion axle. This still isn't ideal because (of necessity bearing in mind the axle it replaces) it has somewhat sharp corners which might lead the axle eventually suffering fatigue in bending. The part number is HSA571 and it replaces HSA534. It also retains the inherently less satisfactory cantilevered planet pinions.

b) it is possible to replace both the axle and the planet cage assembly with those from the 2000 onwards X-RD3. This costs a little more but is a better repair.

There is (I think) a similar story concerning the equivalent NIG-3s coaster brake hubs ( eg AWC models with different axle PNs) but I don't know the details.

2) Actuator plates were of course used on all 5s hubs (post S5-2, i.e. 1991 onwards). In this use they didn't seem to manifest an unusually high failure rate. Cynics might argue that these hubs were liable to break some other way first, and this masked the actuator plate weakness, but I think the true answer is a little more nuanced than that. In particular the highest loads on the actuator plate 'ears' only appear when wheeling the bike backwards and/or backpedalling, and indeed can only appear if the sliding clutch is able to transfer a reverse load through the planet cage. The sliding clutch is ramped where it engages with the planet cage, so it cannot transfer high reverse torque loads without become disengaged, provided it is still free to slide within the driver spline. Once under torque load however, the sliding is inhibited, so the sliding clutch can become jammed, but this doesn't always happen.

If you backpedal a NIG-AW in gear 3, it will either backpedal fairly quietly with a little more resistance than normal (which means the actuator plate/driver freewheel pawl mechanism is working as intended) or it will backpedal rather noisily, with a regular clunking sound, corresponding with visible spasms of slackness in the control toggle. The latter means the sliding clutch is lifting on the reverse torque ramps and it is this which is allowing the backpedalling to occur. [Some folk have run NIG-3s hubs without the actuator plate fitted; I have not done this but if you then wheel the bike backwards you are 100% reliant on the sliding clutch lifting on the reverse ramps; if this doesn't happen the hub will break. Also note that if you remove the actuator plate on a coaster brake hub, or the actuator plate is damaged, probably the brake won't work and/or the hub will break instantly]

I think the big difference between the NIG-5s hubs and the NIG-AW is that the 5s sliding clutches have shallower engagement and have more sloping reverse torque ramps; I think this means that the sliding clutch is more likely to lift away from the planet cage and the actuator plate is less likely to see the highest loads. The other thing is that the sun pinions in a 5s hub are (weakly) spring loaded so there is always a small drag force on the planet cage; this means that the sliding clutch is almost certain to rotate backwards (at least as far as the start of the reverse torque ramps) at an early stage, and this presumably also makes it more likely to then lift.

A simple way of giving the actuator plate an easier life is to

a) not backpedal during gearshifts (IMHO it is almost invariably best to carry on pedalling forwards during shifts in most SA hubs, but without any force applied) and/or

b) try and avoid wheeling the bike backwards, or at least ensure that the pedals are entirely free to turn backwards should you do so. On a large wheeled machine, if you feel any resistance from the hub when wheeling the bike backwards, and the pedals cannot turn (eg because a stand is still down or your leg/a bike is in the way) it is likely that the actuator plate is starting to deform and jam (much as the deformed one in the photo upthread). A deformed actuator plate is very likely to break before too much longer, not least because the deformation may inhibit the driver from ever turning backwards inside the ring gear.

It is easy enough to avoid wheeling the bike backwards on an unladen solo. But a heavy rear loaded bike is very likely to be wheeled backwards (e.g. out of a bike stand/rack/parking) and this is more likely to load the actuator plate up.

cheers

Last edited by Brucey on 17 Mar 2020, 10:08am, edited 1 time in total.

-------------------------------------------------------------------------------

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

-

Carlton green

- Posts: 3699

- Joined: 22 Jun 2019, 12:27pm

Re: Sturmey NIG 3s hub; what to look out for, what breaks.

Whilst not music to my ears it is better to know than not. Sod’s Law does seem to work remarkably well, expecting that the latest version would be the best I’ve just built an SRF3 wheel - it’s a nice tidy job too. As it happened I could have more cheaply and easily used a pre-NIG hub instead, but I went for the later version in the hope of a more secure spare parts supply. Oh well, if the need arises then taking the hub apart isn’t too difficult and I’ll have to see how things turn out for me, but if I build another it will be with a pre NIG hub. The only plus is that the hub was second hand (so cheap) and on internal inspection no wear or other issues were found ... this time.

Don’t fret, it’s OK to: ride a simple old bike; ride slowly, walk, rest and admire the view; ride off-road; ride in your raincoat; ride by yourself; ride in the dark; and ride one hundred yards or one hundred miles. Your bike and your choices to suit you.

Re: Sturmey NIG 3s hub; what to look out for, what breaks.

if you want to you can fit a pre-NIG internal into a SRF3 hubshell. This also gives an easy way of mounting two sprockets if you want to do this, since the pre NIG driver has longer sprocket mounting splines than the standard NIG driver. You can probably obtain a (used) pre-NIG hub complete, overhaul it, and buy a revised axle, all for less than the cost of a BWR driver alone.

cheers

cheers

-------------------------------------------------------------------------------

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

-

Carlton green

- Posts: 3699

- Joined: 22 Jun 2019, 12:27pm

Re: Sturmey NIG 3s hub; what to look out for, what breaks.

Brucey wrote:if you want to you can fit a pre-NIG internal into a SRF3 hubshell. This also gives an easy way of mounting two sprockets if you want to do this, since the pre NIG driver has longer sprocket mounting splines than the standard NIG driver. You can probably obtain a (used) pre-NIG hub complete, overhaul it, and buy a revised axle, all for less than the cost of a BWR driver alone.

cheers

That’s certainly something to consider and a pragmatic way forwards, thank you. As it happens I have a new & long pre NIG axle and a suitable enough overhauled pre NIG hub in my spares box. We’ll see how things go but rather than mix and match between pre and post NIG hubs - which I’ll do if pressed - my preference is to, at some point in time, build the pre NIG parts into a spare wheel to swop in as and when needed. I’ll have to see how things work out for me and my use.

Don’t fret, it’s OK to: ride a simple old bike; ride slowly, walk, rest and admire the view; ride off-road; ride in your raincoat; ride by yourself; ride in the dark; and ride one hundred yards or one hundred miles. Your bike and your choices to suit you.

Re: Sturmey NIG 3s hub; what to look out for, what breaks.

There is absolutely no problem swapping pre-NIG and NIG 3s AW internals in and out of their respective hubshells; they are intended to interchange this way. Indeed the AW3 pictured upthread is tantamount to a NIG AW mechanism in a Nottingham type pre-NIG shell.

FWIW SRF3 hubshells also accept some 4s/5s internals, provided

a) they are long enough; this includes FW, S5, S5-1, S5-2, and SRF5(W) internals (although the last of these is very snug and the dimensions really need to be checked to be sure) but excludes 5-star, and 'sprinter' 5s internals. The excluded internals (in standard form) are too short and you will lose low gear drive to the hubshell. Also

b) the SRF3 hubshell can't be an early one. Early SRF3 hubshells can have a protrusion into the hubshell near the LH bearing (about 6mm high), which is also found in many older AW hubshells . This protrusion, if present, doesn't interfere with either pre NIG or NIG 3s internals but will prevent any 5s internal from being fitted.

AFAICT any SRF3 hubshell manufactured after some point in the mid-noughties ought not to have the protrusion and will therefore accept a wider range of internals without any complications.

cheers

FWIW SRF3 hubshells also accept some 4s/5s internals, provided

a) they are long enough; this includes FW, S5, S5-1, S5-2, and SRF5(W) internals (although the last of these is very snug and the dimensions really need to be checked to be sure) but excludes 5-star, and 'sprinter' 5s internals. The excluded internals (in standard form) are too short and you will lose low gear drive to the hubshell. Also

b) the SRF3 hubshell can't be an early one. Early SRF3 hubshells can have a protrusion into the hubshell near the LH bearing (about 6mm high), which is also found in many older AW hubshells . This protrusion, if present, doesn't interfere with either pre NIG or NIG 3s internals but will prevent any 5s internal from being fitted.

AFAICT any SRF3 hubshell manufactured after some point in the mid-noughties ought not to have the protrusion and will therefore accept a wider range of internals without any complications.

cheers

-------------------------------------------------------------------------------

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

Re: Sturmey NIG 3s hub; what to look out for, what breaks.

A lot of the NIG-3 speed parts in current use go back further than I thought. I've revised the previous posts to reflect the fact that the AT3 model of 1989 appears to use many of them;

including the axle, the ring gear, the planet cage (same as X-RD3), the driver etc, but not (strangely) the sliding clutch. I have no idea what the difference is in the clutch.

The 1990s steelite SAB NIG hub is detailed here (complete with maltese cross piece)

https://hadland.files.wordpress.com/2012/07/steel.pdf

The idea was presumably that the sun pinion (HSA533) could be easily replaced. I have seen plenty broken, but I have never seen one for sale as a spare part.

Given that the AT3 internal already existed, and was used in the steelite model of 1989 too, the main justification for the later 'maltese cross' NIG internal can only have been that it was cheaper to make.

cheers

including the axle, the ring gear, the planet cage (same as X-RD3), the driver etc, but not (strangely) the sliding clutch. I have no idea what the difference is in the clutch.

The 1990s steelite SAB NIG hub is detailed here (complete with maltese cross piece)

https://hadland.files.wordpress.com/2012/07/steel.pdf

The idea was presumably that the sun pinion (HSA533) could be easily replaced. I have seen plenty broken, but I have never seen one for sale as a spare part.

Given that the AT3 internal already existed, and was used in the steelite model of 1989 too, the main justification for the later 'maltese cross' NIG internal can only have been that it was cheaper to make.

cheers

-------------------------------------------------------------------------------

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

Re: Sturmey NIG 3s hub; what to look out for, what breaks.

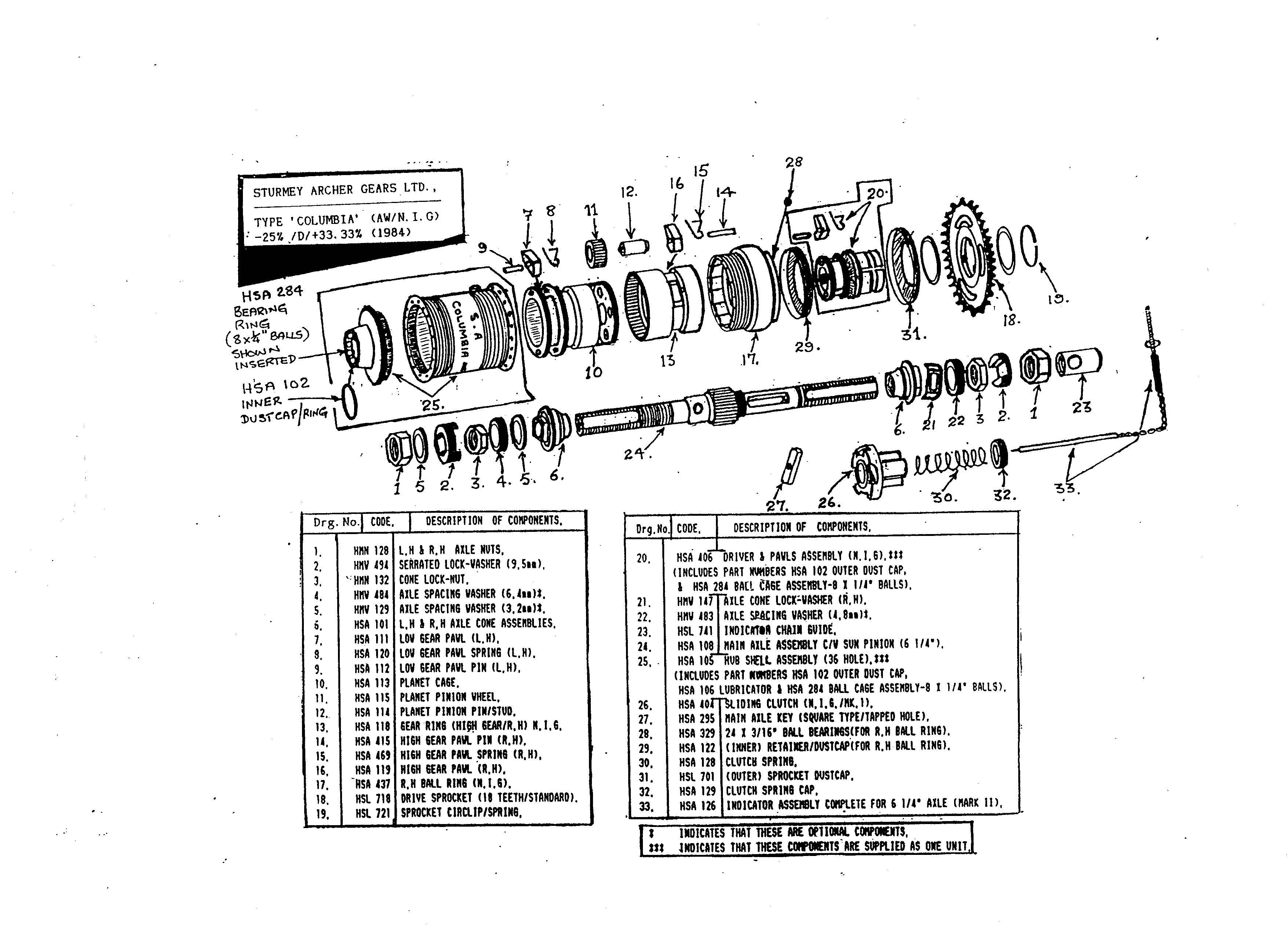

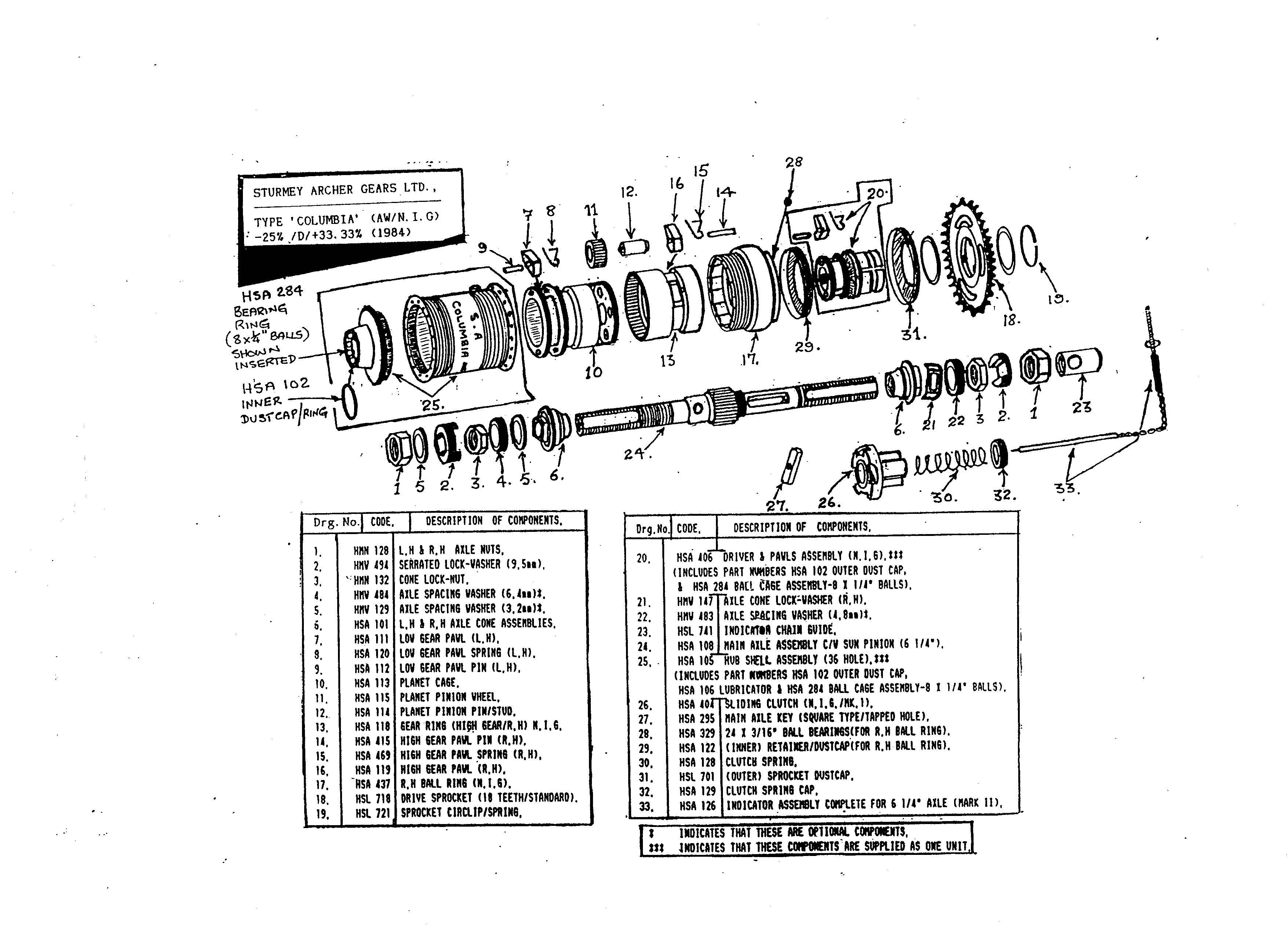

this exploded view of a pre-NIG AW internal contains a few small errors but it gives a very good impression of the parts in this gear.

There are only four pawls; it is a very elegant design in many respects. The internal shown is from the mid 1980s (or later, up to ~2000) and has a 20T dog ring.

The diagram below shows the first modern SA NIG 3s gear from 1984. The NIG specific parts are mostly different from later NIG gears, but the principle of operation is the same, with a driver using two extra pawls and a sliding clutch which only drives in gear 3.

http://www.sturmey-archerheritage.com/images/photos/pic-135.1.jpg

Some of the above NIG-specific parts carried over into the later NIG designs, (for example the toggle key HSA295) but most were changed in later NIG versions.

edit; incidentally I suspect there is an error in the above listing; HSA118 is not a NIG-type ring gear (it was used on S5-2 models amongst other things) and pawl pin HSA415 is the longer pawl pin that is found in NIG type ring gears; it is too long to fit in ring gear HSA118. Ball/dog ring HSA437 is deeper than the standard AW ball ring which would be consistent with the use of a (longer) NIG type ring gear. So I think the ring gear part number above is in error.

Had the NIG version just been 'better' in an unequivocal fashion then I daresay they wouldn't have redesigned it several times before 2000 and it would presumably have just displaced the old pre-NIG design.

cheers

There are only four pawls; it is a very elegant design in many respects. The internal shown is from the mid 1980s (or later, up to ~2000) and has a 20T dog ring.

The diagram below shows the first modern SA NIG 3s gear from 1984. The NIG specific parts are mostly different from later NIG gears, but the principle of operation is the same, with a driver using two extra pawls and a sliding clutch which only drives in gear 3.

http://www.sturmey-archerheritage.com/images/photos/pic-135.1.jpg

Some of the above NIG-specific parts carried over into the later NIG designs, (for example the toggle key HSA295) but most were changed in later NIG versions.

edit; incidentally I suspect there is an error in the above listing; HSA118 is not a NIG-type ring gear (it was used on S5-2 models amongst other things) and pawl pin HSA415 is the longer pawl pin that is found in NIG type ring gears; it is too long to fit in ring gear HSA118. Ball/dog ring HSA437 is deeper than the standard AW ball ring which would be consistent with the use of a (longer) NIG type ring gear. So I think the ring gear part number above is in error.

Had the NIG version just been 'better' in an unequivocal fashion then I daresay they wouldn't have redesigned it several times before 2000 and it would presumably have just displaced the old pre-NIG design.

cheers

Last edited by Brucey on 19 Mar 2020, 9:00pm, edited 2 times in total.

-------------------------------------------------------------------------------

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

Re: Sturmey NIG 3s hub; what to look out for, what breaks.

I have never seen the first NIG hub in the flesh but a thought occurs to me, which is that the (extra) driver pawls in the 1984 NIG hub have a shape which appears to protrude into the centre spline of the driver, which is reminiscent of the main high gear drive pawls. This suggests that these pawls might be 'defeated' by a suitably shaped sliding clutch, in gear 3 only. If so, this might perhaps be a fundamentally more elegant solution (to the problem of the driver being attached simultaneously to both the ring gear and the planet cage in third gear) than the actuator plate is. Doubtless there would be some quirk or other in the operation of such an arrangement, there usually is….

cheers

cheers

-------------------------------------------------------------------------------

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

Re: Sturmey NIG 3s hub; what to look out for, what breaks.

below is an example of a 'maltese cross' type NIG three speed internal (from the late 1990s, in a steelite hub) but where the maltese cross part itself has been omitted. Everything else is pretty much the same with this version of the internal. The broken axle is the sort with a pin/rivet through it, and has broken at the hole. The usual failure seen is a failed sun pinion, but the whole thing isn't that strong in this hub variant.

cheers

cheers

-------------------------------------------------------------------------------

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

Re: Sturmey NIG 3s hub; what to look out for, what breaks.

interestingly there is a paragraph on p8 herehttp://www.sturmey-archerheritage.com/files/view-14.pdf(p7 in the original document) extolling the virtues of NIG operation of the 1908 SA 3s gear.

It mentions that other gears, unlike theirs, leave the transmission in neutral when shifting gears (or presumably when the mechanism is out of adjustment), leading to a risk of slippage. "This we have found is absolutely dangerous to the rider" they say. Yet less than thirty years later they were happily manufacturing gears which did exactly that, and said gear went on to become the most common 3s gear ever manufactured.

So faced with a choice of making an expensive NIG hub or a more profitable non-NIG hub, they eventually decided to take the money and run....?

cheers

It mentions that other gears, unlike theirs, leave the transmission in neutral when shifting gears (or presumably when the mechanism is out of adjustment), leading to a risk of slippage. "This we have found is absolutely dangerous to the rider" they say. Yet less than thirty years later they were happily manufacturing gears which did exactly that, and said gear went on to become the most common 3s gear ever manufactured.

So faced with a choice of making an expensive NIG hub or a more profitable non-NIG hub, they eventually decided to take the money and run....?

cheers

-------------------------------------------------------------------------------

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

~~~~~~~~~~~~~~~~~~~~~~Brucey~~~~~~~~~~~~~~~~~~~~~~~~

Re: Sturmey NIG 3s hub; what to look out for, what breaks.

Fantastic info Brucey, excellent reading for someone who really admires these brilliant hubs.